Choosing the right industrial aluminum profile frame custom manufacturer is crucial. A reliable partner provides precision, durability, and cost savings. The demand for aluminum-extrusion-customization is rapidly increasing across various sectors. The market is projected to expand from $912 million in 2025 to $1.36 billion by 2033, indicating a growing need for quality manufacturers, particularly in the product-category/door-and-window-moving-door-custo segment.

Key Takeaways

- Clearly know what your project needs. Understand the kind of aluminum profile you need for your project to make sure it fits well.

- Check manufacturers for their experience and certifications. Pick companies with good history and proper certifications to ensure quality.

- Look for custom options. Choose a manufacturer that can create designs and functions just for your needs.

Define Your Needs

Know Your Project Details

Before picking a manufacturer, figure out your project needs. Start by deciding the type of aluminum profile you require. Do you need general profiles, rectangular tubes, or special shapes like Z or H channels? Each type has a specific use, like for frames, braces, or detailed designs.

Here’s a simple table to guide you:

| Profile Type | Length (m) | Minimum Wall Thickness (mm) | Maximum Dimensions (Circumscribed Circle Diameter mm) | Workability | Uses |

|---|---|---|---|---|---|

| General Aluminum Profile | 0.2 to 14 (custom) | 0.4 | 300 | Easy to Weld, Cut, Machine | Frames, Supports, Braces, Trailers, etc. |

| Aluminum Rectangular Tube | 0.2 to 14 (custom) | 0.4 | 300 | Easy to Weld, Cut, Machine | N/A |

| Aluminum Square Tube & Bar | 0.2 to 14 (custom) | 0.4 | 300 | Easy to Weld, Cut, Machine | Frames, Supports, Braces, Trailers, etc. |

This table shows how flexible aluminum profiles are. It helps you match your project with the right product.

Think About Strength and Structure

Consider how much weight your frame will hold. For heavy-duty projects, pick profiles with thicker walls and more strength. Aluminum is light but strong, making it great for sturdy designs without extra weight. For example, H channels work well for heavy frameworks.

Ask yourself: Will the frame face tough conditions like heat or vibrations? If yes, choose profiles that are stronger and more durable.

Focus on Looks and Design

Custom aluminum profiles give you lots of design options. You can pick unique shapes, sizes, and finishes to match your project’s style. Whether hiding LED strips for a modern look or making fancy furniture, aluminum profiles can make your ideas real.

Here’s a comparison of custom and standard profiles:

| Function | Standard Profiles | Custom Profiles |

|---|---|---|

| Flexibility | Limited shapes and sizes | Many design options (shape, size, finish) |

| Lead Time | Short (ready-made items) | Longer (custom production needed) |

| Initial Costs | Low (no extra tools needed) | Higher (tooling costs for new designs) |

Custom profiles help create a clean, polished look. They also improve function, like reducing glare or hiding wires.

Evaluate Manufacturer Expertise

When picking a custom aluminum frame maker, check their skills. A good manufacturer ensures your project is smooth and successful. Let’s see how to review their experience, certifications, and focus areas.

Check Experience in Custom Aluminum Profiles

Experience is key. Makers with many years of work know a lot. They’ve handled different projects and can manage tough tasks. Experienced companies also have better tools for quality work.

The demand for aluminum profiles is growing in many industries. This table shows how skilled makers meet this need:

| Market Segment | Market Size (2024) | Projected Size (2033) | CAGR (%) |

|---|---|---|---|

| High-end Aluminum Profile Market | USD 8.5 Billion | USD 12.3 Billion | 4.5% |

| Automotive Extruded Aluminium Profiles | USD 3.12 Billion | USD 5.67 Billion | 7.2% |

These numbers highlight why choosing an experienced maker is smart. For example, JIJU ALUMINIUM, with 30+ years of work, delivers top-quality profiles for industries like construction and electronics.

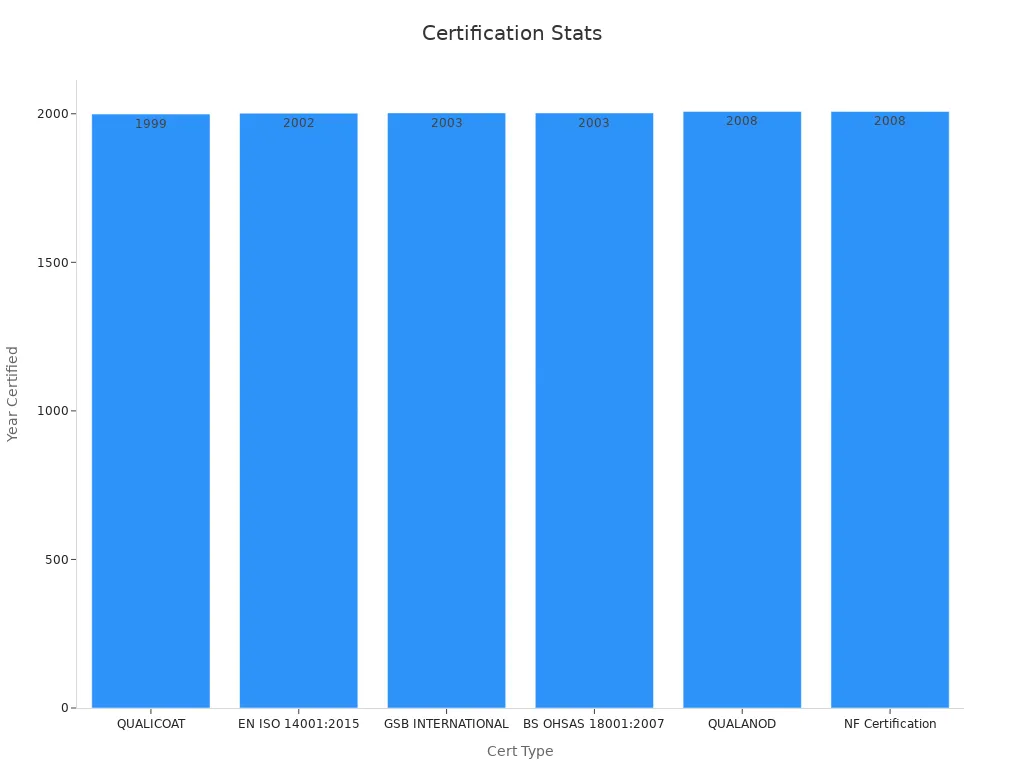

Look for Certifications and Standards

Certifications show a company cares about quality and rules. They prove the maker follows industry standards. Ask about certifications like ISO 9001 for quality or ISO 14001 for the environment.

Here’s a table of common certifications and their meanings:

| Certification Type | Description | Year Certified | Certifying Body |

|---|---|---|---|

| QUALICOAT | Powder coating certification for aluminium profiles | 1999 | Hellenic Aluminium Association |

| EN ISO 9001 | Quality Management System | N/A | TÜV NORD CERT |

| EN ISO 14001:2015 | Environmental Management System | 2002 | TÜV NORD CERT |

| QUALANOD | Certificate of anodizing quality assurance | 2008 | Hellenic Aluminium Association |

These certifications ensure good materials and eco-friendly practices. For instance, JIJU ALUMINIUM has ISO 9001:2015 and ISO 14001:2015, proving their high standards.

Find Specialization for Your Needs

Not all makers are the same. Some focus on specific uses, which helps your project. For example, if you need profiles for medical tools, pick a maker who knows that field.

Here’s a comparison of benefits between general and specialized makers:

| Benefit | Composites | Aluminum Extrusion |

|---|---|---|

| Strength-to-weight ratio | Higher | Lower |

| Corrosion resistance | Excellent | Moderate |

| Design flexibility | High | Limited |

| Electrical insulation | Yes | No |

| Thermal insulation | Yes | No |

Specialized makers, like JIJU ALUMINIUM, offer custom solutions for industries like furniture and transport. Their services, like mold design and CNC machining, ensure your project gets expert care.

By focusing on experience, certifications, and specialization, you can pick the best aluminum frame maker for your needs.

Assess Quality Standards

When picking a manufacturer for aluminum profile frames, quality matters most. Here’s how to check their standards.

Check Industry Standards

See if the manufacturer follows important industry rules. Certifications like ISO 9001:2015 show they focus on quality. ISO 14001:2015 proves they care about the environment. These certifications mean the company uses strict methods to make good products.

Look for special certifications like QUALICOAT for powder coating or QUALANOD for anodizing. These ensure strong finishes and long-lasting profiles. Good manufacturers often show these certifications on their website or share them if asked.

Tip: Always ask for proof of certifications. It’s your right to know.

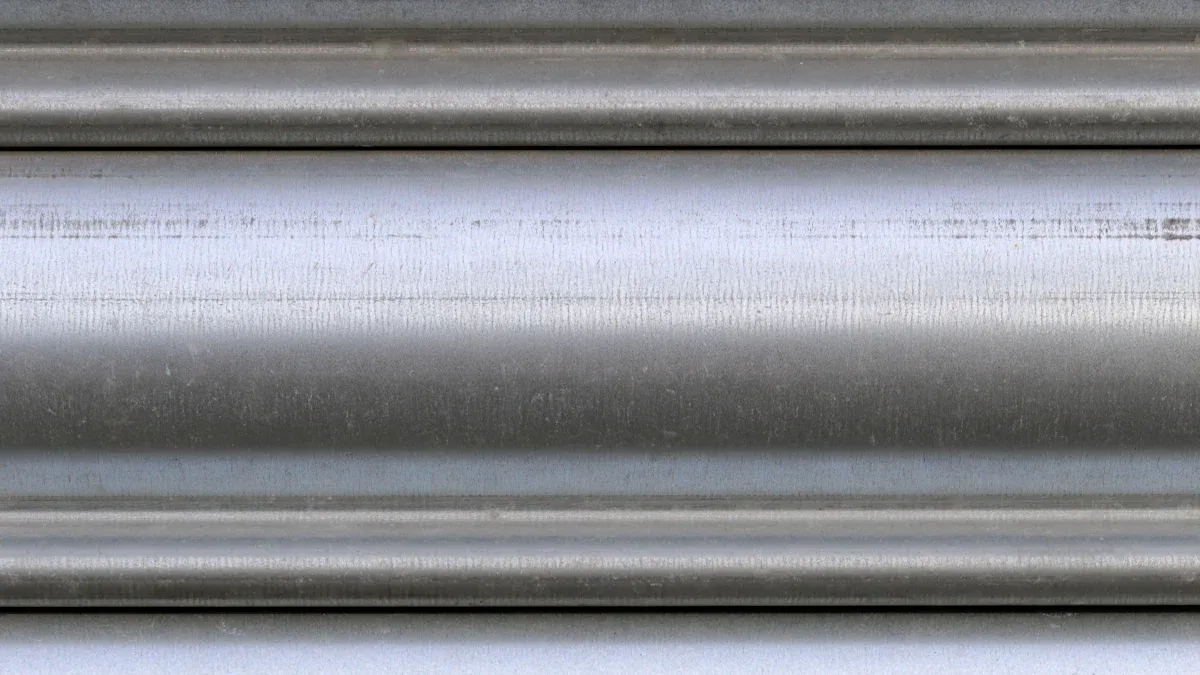

Review Material Quality and Strength

The type of aluminum used affects how strong the frames are. High-quality alloys like 6061 or 6063 are strong and resist rust. Ask the manufacturer about the aluminum they use and if it fits your needs.

Durability is key too. Will the frames handle tough conditions like heat or heavy loads? A good maker will explain the material’s features, like its strength and wear resistance.

Request samples to check the material yourself. Look for smooth surfaces, even thickness, and no flaws. A quick look can tell you a lot about their quality.

Examine Production Methods and Tools

Modern tools and processes help make better aluminum profiles. Manufacturers with advanced machines create precise and consistent products. CNC machines cut accurately, and automated extrusion tools reduce mistakes.

Ask if the company does everything in-house, like mold design and surface finishing. In-house work often means better quality control. For example, JIJU ALUMINIUM uses 21 advanced machines and offers services like welding and sawing. This ensures your frames meet your exact needs.

Note: Companies with updated technology usually deliver better and smarter solutions.

By checking standards, materials, and production methods, you can choose a manufacturer that values quality. This ensures your aluminum frames will last and work well over time.

Customization and Support

Find a Manufacturer Offering Custom Solutions

Not all aluminum profiles work for every project. You need a company that can create custom designs for your specific needs. Whether it’s fancy furniture or strong industrial frames, customization makes your project unique.

Here’s how custom options can help:

| Application Type | Custom Features | Benefits |

|---|---|---|

| Air Handling Unit | Adjustable sizes, shapes, and configurations | Helps engineers solve specific problems with more flexibility. |

| Architectural Designs | Teamwork with clients and modern technology | Creates amazing designs that go beyond expectations. |

| Aluminum Joints | Unique designs with decorative details | Improves both looks and usefulness in building projects. |

Choosing a company like JIJU ALUMINIUM gives you access to advanced tools. They offer services like mold creation and surface finishing to make your project special.

Get Help During the Design Process

Designing custom profiles can be hard. That’s why it’s important to pick a company that helps with design. They can suggest the best materials, sizes, and finishes for your project. For example, JIJU ALUMINIUM has 45 experts who make sure your design is smart and affordable.

Check for Warranties and Support After Purchase

Good support after buying is very important. A trustworthy company offers warranties and helps fix any problems. This makes you feel secure about your purchase. Look for services like repair tips or replacement guarantees to stay satisfied for a long time.

By working with a custom aluminum profile manufacturer that focuses on custom designs and support, your project will turn out great.

Compare Costs and Delivery

Balance Cost with Quality

Picking the cheapest option might seem smart, but it’s not always best. Low prices can mean lower quality. Good aluminum profiles last longer and work better. This saves money over time.

Understand what makes prices go up. Custom profiles need special tools, and complex designs cost more. Other factors like alloy type, finishes, and custom features also matter. For example:

- Simple shapes cost less than detailed, custom designs.

- Finishes like anodizing or powder coating make profiles stronger but add to the price.

Knowing these details helps you choose wisely without losing quality.

Ask for Clear Quotes

Before choosing a manufacturer, ask for a detailed price list. A good company explains costs clearly. This shows where your money goes. Look for details like:

- Costs for making special tools.

- Prices for raw aluminum, which can change.

- Extra services like surface finishing or cutting.

Clear quotes help you compare companies fairly. If a company won’t explain costs, it’s a warning sign.

Check Delivery Times

Getting your order on time is very important. Late deliveries can mess up plans and cost more money. Ask about delivery times and how they handle delays. Reliable companies often share their delivery records.

For example:

- Over 40% of business leaders said delays raised costs by 5% or more.

- Some companies, like Macy’s, had shipments delayed by almost 10 days.

Pick a manufacturer known for delivering on time. This keeps your project on track and avoids extra costs.

By focusing on price, clear quotes, and delivery reliability, you can find a manufacturer that fits your needs and budget.

Customer Reviews and Reputation

Read customer feedback and opinions

Customer reviews help you understand if a manufacturer is trustworthy. Before choosing, read what others say about them. Start with testimonials on their website, but also check other places. Look at review sites or forums where people share honest thoughts.

Notice common points in the reviews. Are customers happy with the product’s quality? Do they mention fast deliveries or helpful support? Good reviews often talk about these things. If you see repeated complaints about delays or bad communication, it’s a warning sign.

Tip: Don’t just look at star ratings. Read the comments to learn more about how the manufacturer performs.

Check their reputation in the industry

A company’s reputation shows how reliable they are. Manufacturers with years of success, like JIJU ALUMINIUM, usually have a strong name in the industry. You can check this by seeing if they’ve won awards or been recognized by industry groups.

Talking to people in your field can also help. Ask coworkers or partners if they’ve worked with the manufacturer. Recommendations from people you trust are often better than online reviews.

Look at examples of their past work

Case studies show what a manufacturer can do. Find examples of projects like yours. Did they finish on time? Were the custom designs good?

Many companies share their past work on their websites. For example, JIJU ALUMINIUM shows its skills in areas like construction and transport. These examples can make you feel confident about their ability to handle your project.

Note: Case studies often show problems the manufacturer solved, which proves their ability to handle challenges.

Picking the right custom aluminum profile frame maker is very important. It helps your project succeed. To choose wisely, think about your needs, the maker’s skills, and their quality. Focus on trust and reputation instead of just low prices. This will give you better results in the long run.

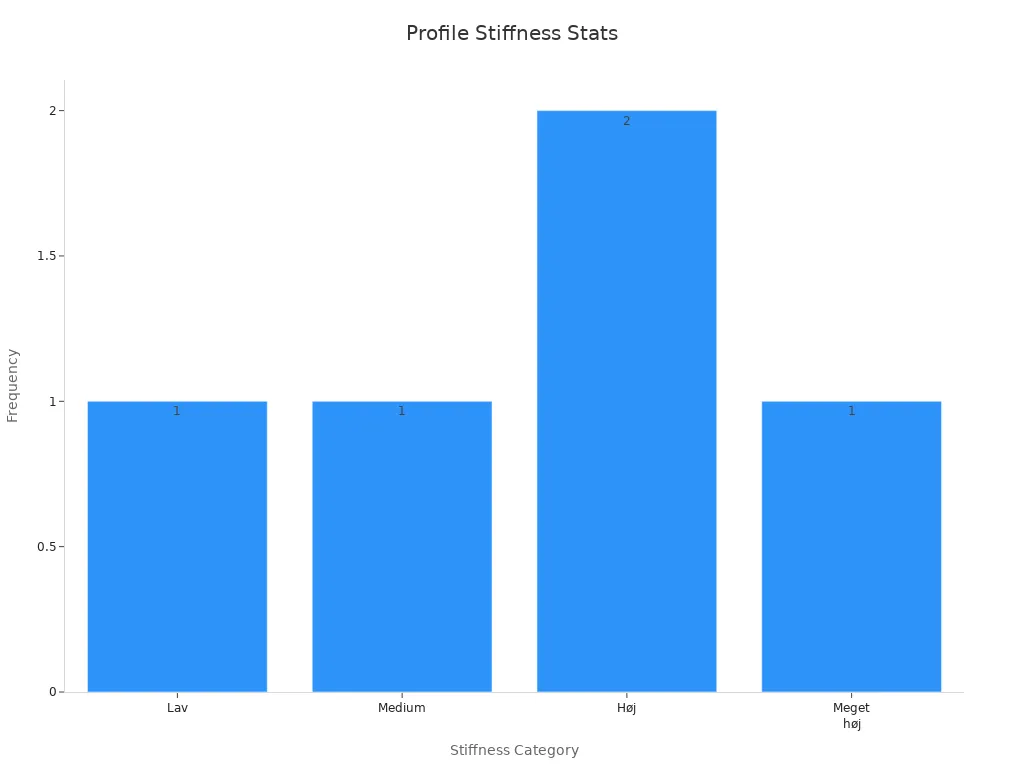

Here’s a simple guide to match profile types with your project’s weight needs:

| Profile Series | Stiffness Level | Typical Load Use | Extra Info |

|---|---|---|---|

| 20×20 | Low | Very Light (Sensors, Small Guards) | Not for heavy structures |

| 40×40 (Standard) | Medium | Light/Medium (Workstations, Jigs) | Popular for general use |

| 40×80 (Standard) | High | Medium/High (Machine Bases) | Strong along the 80mm side |

| 45×45 (Heavy Duty) | High | High (Strong Frames, Light Gantries) | Thicker walls than regular profiles |

| 45×90 (Heavy Duty) | Very High | Very High (Heavy Machines, Gantries) | Built for big structural loads |

By using these tips, you can pick a manufacturer that fits your needs and delivers great results.

FAQ

Which industries use custom aluminum profiles the most?

Custom aluminum profiles are useful in construction, transport, and electronics. They’re also ideal for furniture, medical tools, and green energy projects. Their strength and flexibility make them a top choice.

Check for certifications like ISO 9001:2015 or QUALICOAT. These show the company follows strict quality rules. Read reviews and ask for samples to check their products.

Tip: Always ask about the materials and tools they use. Strong alloys like 6061 or 6063 resist rust and last longer.

Can manufacturers help with custom aluminum profile designs?

Yes! Many companies, like JIJU ALUMINIUM, offer design help. They’ll suggest the best materials, sizes, and finishes for your project.

Emoji Insight: 🛠️ Design help makes your project easier and better!