I deliver 6061 alloy solutions with unmatched precision at JIJU ALUMINIUM. My team provides custom extrusion, deep processing, and tailored profiles that meet strict requirements. Customers rely on me to supply high-performance 6061 alloy products for everything from structural frames to intricate components. I maximize the alloy’s natural strength, corrosion resistance, and workability to ensure every project succeeds.

Key Takeaways

1.JIJU Aluminium delivers high-quality 6061 alloy products by carefully selecting pure raw materials and using advanced purification methods.

2.Strict quality control and recognized certifications ensure consistent alloy performance and build customer trust.

3.Advanced manufacturing equipment like extrusion lines and CNC centers produce precise, custom 6061 alloy profiles with excellent surface treatments.

4.Custom solutions include tailored shapes, fast lead times, and deep processing to meet diverse industry needs.

5.Expert technical support guides customers from pre-sales consultation to after-sales maintenance for smooth project success.

6.JIJU Aluminium offers cost-effective pricing with transparent quotes and efficient logistics for timely, reliable delivery worldwide.

7.Environmental responsibility and quality certifications guarantee eco-friendly production and high product standards.

8.The company serves many industries, providing lightweight, strong, and durable 6061 alloy solutions that improve product performance.

6061 Alloy Quality

Purity

Raw Material Selection

I always start with the best raw materials. I choose only high-grade aluminum ingots that meet strict chemical composition standards. My suppliers must provide detailed certificates for every batch. This careful selection process helps me avoid impurities that could weaken the final product. I know that the foundation of a reliable 6061 alloy begins with the right ingredients.

Purification

After selecting the raw materials, I use advanced purification methods. I remove unwanted elements through precise melting and filtering techniques. My team monitors every step to ensure the alloy remains clean and consistent. This attention to detail allows me to deliver 6061 alloy with excellent purity, which leads to better mechanical properties and longer service life.

Consistency

Quality Control

I believe that consistency sets my products apart. My quality control team inspects every stage of production. We use spectrometers and other advanced tools to check the chemical composition. I also run mechanical tests to confirm that each batch meets the required standards. My process includes regular audits and spot checks, so I can catch any issues before they reach the customer.

Certification

I back up my quality claims with recognized certifications. My facility operates under ISO 9001 standards. I provide full traceability for every order. Customers receive documentation that proves the 6061 alloy meets international requirements. This transparency builds trust and ensures peace of mind for every project.

Performance

Strength

I optimize the 6061 alloy to achieve high strength. My team controls the heat treatment process to enhance the alloy’s mechanical properties. We test tensile strength and yield strength for every batch. This approach guarantees that my products can handle demanding structural applications without failure.

Corrosion Resistance

I know that corrosion resistance is critical for many industries. My 6061 alloy resists rust and environmental damage, even in harsh conditions. I use precise alloying and surface treatments to boost this property. Customers rely on my products for outdoor structures, marine parts, and other challenging environments.

Tip: Always ask for quality certificates and test reports when sourcing 6061 alloy. This ensures you get the performance you expect.

Manufacturing

Equipment

Extrusion Lines

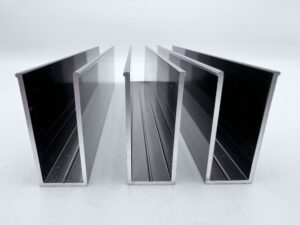

I invest in advanced extrusion lines to deliver precise 6061 alloy profiles. My workshop features multiple automated presses that handle a wide range of shapes and sizes. Each line operates with strict temperature and speed controls. This setup allows me to maintain tight tolerances and consistent quality. I monitor every stage, from billet heating to profile cooling, to ensure the final product matches your exact specifications.

Note: My extrusion lines can produce both standard and complex custom profiles. I adapt quickly to new project requirements.

CNC Centers

I rely on high-precision CNC centers for deep processing. My machines cut, drill, and mill 6061 alloy parts with exceptional accuracy. I program each CNC center to follow detailed CAD drawings. This approach guarantees that every component meets your design needs. My team inspects each part after machining to confirm flawless execution.

Surface Treatment

Oxidation

I use oxidation to enhance the durability of my 6061 alloy products. My anodizing process creates a tough, protective layer on the surface. This layer resists scratches and corrosion. I control the thickness and color of the oxide layer to match your application. My oxidation process also improves the appearance of the final product.

Spraying

I offer professional spraying services for additional surface protection and aesthetics. My team applies uniform coatings using automated spray booths. I use high-quality paints and powders that bond tightly to the alloy. This step adds color, increases weather resistance, and extends the product’s lifespan. I can match any color you specify.

Capacity

Annual Output

I maintain a high annual output to meet large and small orders. My facility produces thousands of tons of 6061 alloy products each year. I optimize my workflow to reduce lead times and ensure timely delivery. My production planning system tracks every order from start to finish.

| Year | Output (Tons) |

| 2022 | 12,000 |

| 2023 | 13,500 |

One-Stop Service

I provide a true one-stop service for 6061 alloy solutions. You can rely on me for everything from raw material selection to final surface treatment. My integrated process saves you time and reduces costs. I coordinate every step, so you receive finished products ready for immediate use.

Tip: Choose a supplier with full in-house capabilities. This ensures better quality control and faster turnaround.

6061 Alloy Customization

I specialize in delivering custom 6061 alloy solutions that fit your exact needs. My expertise covers every step, from mold design to deep processing. I help you achieve lightweight, durable, and cost-effective results for any application.

Custom Profiles

Mold Design

I design molds with precision. My engineering team uses advanced CAD software to create molds that match your drawings. I review every detail to ensure the final profile meets your requirements. My process reduces waste and speeds up production. I can adapt quickly if you need changes.

Tailored Shapes

I produce tailored shapes for unique projects. My extrusion lines handle complex cross-sections and non-standard dimensions. I work closely with you to understand your application. I deliver profiles that fit perfectly, whether you need a simple bar or an intricate frame.

Note: My typical lead time for custom 6061 alloy profiles is fast. For orders up to 500 kg, I deliver in about 15 days. Larger orders may take longer, but I always discuss timelines with you in advance.

| Order Quantity (kg) | Typical Lead Time (days) |

| 1 to 500 | 15 |

| More than 500 | Negotiable |

Deep Processing

Machinability

I take full advantage of the excellent machinability of 6061 alloy. My CNC centers cut, drill, and mill with high accuracy. I achieve tight tolerances and smooth finishes. My team checks every part to ensure it matches your specifications.

Workability

I know that workability matters for your project. I bend, weld, and assemble 6061 alloy profiles with ease. My processes keep the material’s strength and surface quality intact. I help you save time and reduce costs by delivering ready-to-use components.

Industry Solutions

I serve a wide range of industries with my 6061 alloy customization services. My solutions help you meet technical challenges and improve product performance.

1.Building and Construction: My customized aluminum profiles provide thermal insulation. You can reduce energy consumption in your buildings.

2.Automotive: I offer profiles that are light and strong. You benefit from lower transport energy and reliable structural strength.

3.Solar Energy: I use recyclable aluminum to support energy efficiency. My frames help you build sustainable solar panels.

4.Electronics and Appliances: My profiles enhance thermal management. You get flexible designs for heat dissipation and lightweight parts.

5.Furniture and Interior Design: I enable sleek, durable, and multifunctional furniture. My solutions address space constraints in urban living.

6.Industrial Machinery and Equipment: My aluminum alloys provide strength similar to steel at about one-third the weight. You can build heavy-duty machinery that is easier to move and install.

7.Medical: I deliver precision profiles for medical equipment. You receive components that meet strict hygiene and safety standards.

8.Tip: Customization lets you optimize every aspect of your product. You can achieve better performance, lower weight, and reduced costs with my 6061 alloy solutions.

Support

Expertise

Experience

I have spent years mastering 6061 alloy solutions. My journey began with hands-on work in extrusion workshops. I learned every detail of the process, from raw material inspection to final product delivery. Over time, I handled projects for many industries, including construction, transportation, and electronics. Each project taught me new ways to solve technical challenges. I use this experience to guide customers through every step. My background helps me anticipate issues and deliver results that exceed expectations.

Technical Team

My technical team stands as my strongest asset. I select engineers who share my passion for precision and innovation. Each member brings specialized skills in metallurgy, mechanical design, and quality control. We hold regular training sessions to stay updated on the latest industry standards. My team works closely with customers to translate ideas into practical solutions. We review every drawing, test every prototype, and refine every process. This teamwork ensures that you receive reliable, high-performance 6061 alloy products.

Tip: When you work with me, you gain access to a team that treats your project as their own.

Consultation

Pre-Sales

I believe that strong support starts before you place an order. My pre-sales consultation helps you clarify your needs and choose the right 6061 alloy solution. I review your drawings, discuss your application, and suggest the best profiles or processing methods. My team provides samples and technical data so you can make informed decisions. I answer questions quickly and honestly, making sure you feel confident from the start.

Application Guidance

I offer detailed application guidance for every project. My engineers analyze your requirements and recommend the most suitable alloy tempers, surface treatments, and fabrication techniques. I help you optimize your design for strength, weight, and cost. My advice covers everything from assembly methods to corrosion protection. You can rely on my expertise to avoid common pitfalls and achieve the best results.

Note: Early consultation often saves time and money by preventing design changes later.

After-Sales

Ongoing Support

My commitment does not end with delivery. I provide ongoing support to ensure your satisfaction. If you have questions about installation or performance, I respond quickly. My team tracks every order and follows up to confirm that the products meet your expectations. I keep communication open so you always know who to contact.

Maintenance

I help you extend the life of your 6061 alloy products. My team offers maintenance tips and troubleshooting advice. We explain how to clean, inspect, and protect your aluminum components. If you need replacement parts or repairs, I arrange fast service. My goal is to keep your operations running smoothly with minimal downtime.

| Support Service | Response Time | Availability |

| Technical Support | Within 24 hrs | Mon-Sat |

| Maintenance Advice | Within 48 hrs | Mon-Fri |

| Replacement Parts | As needed | Year-round |

Callout: I stand by every product I deliver. My support makes your experience with JIJU ALUMINIUM easy and worry-free.

Value

Pricing

Cost-Effectiveness

I always focus on delivering cost-effective solutions for my customers. My production process uses advanced automation and efficient resource management. This approach helps me reduce waste and control costs. I pass these savings directly to you. You get high-quality 6061 alloy products without paying extra for unnecessary overhead. I believe that value comes from both performance and price. My goal is to help you achieve the best results within your budget.

Tip: Ask me about bulk order discounts or long-term supply agreements. I can often provide even better pricing for ongoing partnerships.

Transparent Quotes

I provide clear and detailed quotes for every project. My quotes break down all costs, including materials, processing, surface treatment, and delivery. You see exactly what you pay for—no hidden fees or surprises. I respond quickly to quote requests and update you if any changes occur. This transparency builds trust and helps you plan your project with confidence.

| Service Item | Included in Quote? |

| Raw Material | ✅ |

| Processing | ✅ |

| Surface Treatment | ✅ |

| Packaging | ✅ |

| Delivery | ✅ |

| After-Sales Support | ✅ |

Delivery

Logistics

I manage logistics with precision. My team coordinates every step, from production scheduling to final shipment. I use reliable carriers and track each order in real time. You receive regular updates on your order status. My logistics system minimizes delays and ensures your products arrive safely and on time.

1.I offer flexible delivery options.

2.I can arrange just-in-time shipments for urgent projects.

3.I provide secure packaging to protect your products during transit.

International Shipping

I support customers worldwide. My export team handles all customs paperwork and compliance checks. I work with trusted international freight partners to deliver your 6061 alloy products anywhere you need them. I understand the challenges of global shipping and help you avoid common pitfalls. You can rely on me for smooth, hassle-free international deliveries.

Note: I can provide shipping estimates and delivery timelines for any destination. Just let me know your requirements.

Certifications

Quality

I back every product with recognized quality certifications. My facility operates under ISO 9001 standards. I test each batch of 6061 alloy for strength, composition, and performance. I provide certificates and test reports with every shipment. You can trust that my products meet strict international standards.

Environment

I care about environmental responsibility. My production process meets ISO 14001 environmental standards. I use energy-efficient equipment and recycle waste materials. I help you meet your own sustainability goals by supplying eco-friendly 6061 alloy solutions.

Callout: When you choose JIJU ALUMINIUM, you get value that goes beyond price. I deliver quality, reliability, and peace of mind with every order.

I make sourcing 6061 alloy simple and reliable. My expertise covers every stage, from raw material selection to final delivery. I offer custom solutions, advanced manufacturing, and ongoing support. My customers trust me to deliver value and performance every time. Ready to experience the difference? Contact me today and see how my 6061 alloy solutions can elevate your next project.

FAQ

What is the minimum order quantity for custom 6061 alloy profiles?

I accept orders as small as 1 kilogram for custom profiles. I want to support both small-scale prototypes and large production runs. You can contact me for specific project requirements.

How fast can you deliver 6061 alloy products?

I deliver standard profiles within 7 days. For custom orders up to 500 kg, I usually ship in about 15 days. I always discuss timelines with you before confirming your order.

Can you provide test reports and certifications with each order?

Yes, I include full test reports and ISO 9001 certificates with every shipment. You receive documentation for chemical composition, mechanical properties, and traceability.

What surface treatments do you offer for 6061 alloy?

I offer anodizing, powder coating, and painting. My team can match your color and finish requirements. I recommend anodizing for maximum corrosion resistance.

Tip: Ask me for samples of different finishes to compare appearance and durability.

Do you support international shipping?

I ship worldwide. My export team handles customs paperwork and compliance. I work with reliable freight partners to ensure safe and timely delivery.

How do I get technical support after receiving my order?

You can contact me by email or phone. My technical team responds within 24 hours. I provide ongoing support for installation, maintenance, and troubleshooting.

What industries do you serve with 6061 alloy solutions?

I serve many industries, including:

Construction

Automotive

Solar energy

Electronics

Furniture

Machinery

Medical

Note: I tailor my solutions to meet your industry’s unique requirements.