I trust JIJU ALUMINIUM to deliver special-shaped aluminum profiles that meet high standards for strength and reliability. I rely on their use of 6063-T6 alloy, which provides excellent durability and corrosion resistance. Over three decades, I have seen their advanced manufacturing and customer-focused approach set them apart. Their products serve many industries, including construction, transportation, and consumer goods, as shown below:

| Application Type | Examples |

| Architectural Applications | Window frames, door frames, curtain walls |

| Structural Applications | Bridges, railings, durable structures |

| Transportation | Lightweight vehicle parts, public transport |

| Consumer Products | Ladders, furniture, frames |

Key Takeaways

1.JIJU ALUMINIUM specializes in custom aluminum profiles, offering tailored solutions for unique project needs.

2.The 6063-T6 alloy provides exceptional strength and corrosion resistance, making it ideal for demanding applications.

3.Their collaborative approach ensures clear communication and support throughout the design and production process.

4.Advanced manufacturing techniques, including CNC machining, guarantee precision and high-quality finishes.

5.Lightweight aluminum profiles simplify installation, reducing labor costs and speeding up project timelines.

6.JIJU ALUMINIUM’s commitment to quality is backed by multiple industry certifications, ensuring reliable performance.

7.The company offers flexible order quantities, accommodating both small prototypes and large-scale projects.

8.Sustainable practices and recyclable materials align with modern environmental standards, promoting eco-friendly projects.

Special-shaped aluminum profiles customization

Design expertise

Experience

I have worked with JIJU ALUMINIUM for many years. Their experience in the field of special-shaped aluminum profiles stands out. Over the past 30 years, I have seen their team tackle projects that require unique shapes and precise specifications. They understand the challenges that come with custom designs. Their knowledge helps me achieve results that meet both technical and aesthetic requirements.

Technical team

JIJU ALUMINIUM’s engineering team impresses me with their skills. The team includes experts in extrusion, surface treatment, and deep processing. I rely on their ability to solve complex design problems. They use advanced software and equipment to turn ideas into reality. Their technical support guides me through every stage, from concept to finished product.

Tailored solutions

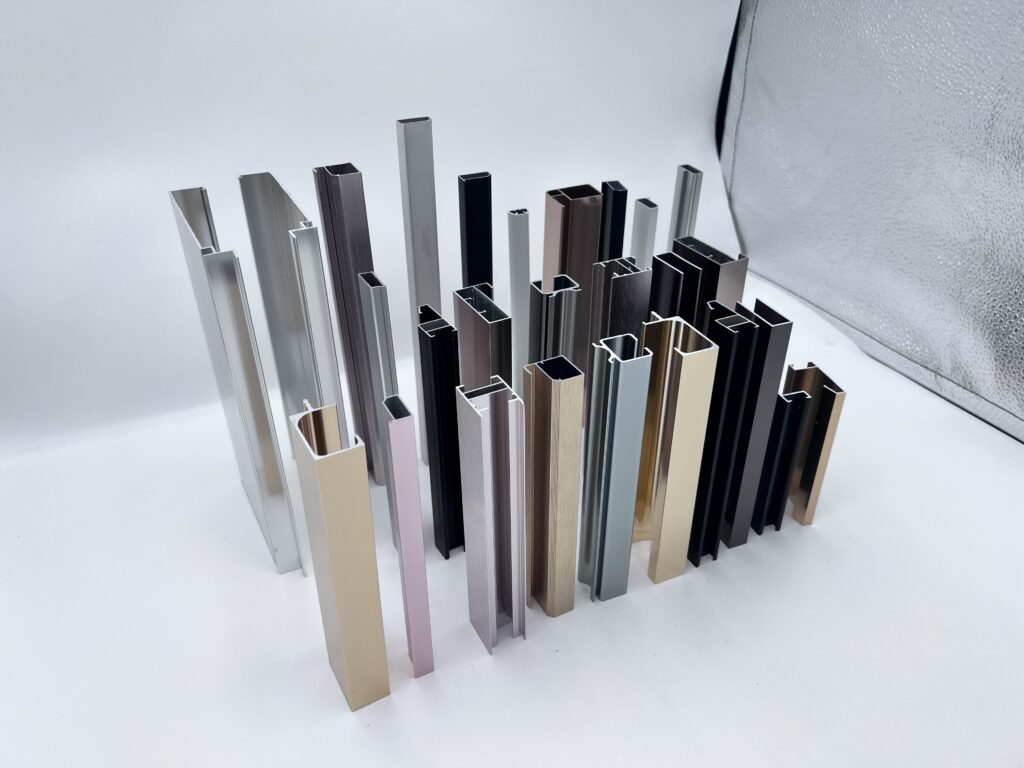

Mold opening

When I need a custom profile, JIJU ALUMINIUM starts with mold opening. Their process ensures that each mold matches my specifications. The company follows a clear development path for tailored solutions:

| Step | Description |

| 1 | Custom mold design for unique profiles |

| 2 | Deep processing for complex parts |

| 3 | Adjustable oxide layer thickness |

| 4 | Wide selection of colors and textures |

This approach allows me to create special-shaped aluminum profiles that fit my project perfectly.

Collaboration

I value the collaborative process at JIJU ALUMINIUM. Their team communicates with me at every stage. They listen to my requirements and offer suggestions that improve the final product. I work closely with their engineers to adjust designs and select finishes. This partnership leads to solutions that exceed my expectations.

Tip: Aluminum’s flexibility opens up new possibilities for design. I can choose from various tempers and alloys, which gives me freedom to create profiles that meet performance standards. I often select intricate shapes that enhance both residential and commercial spaces. Custom extrusion lets me develop complex profiles that improve functionality and aesthetics. This flexibility encourages innovation in every project.

Quality and materials

6063-T6 alloy

Durability

I always choose 6063-T6 alloy for my projects because it offers outstanding mechanical properties. This alloy gives me confidence that my designs will last and perform under stress. I see the difference in its strength and resilience every time I use it. Here are some key mechanical properties that make 6063-T6 ideal for special-shaped aluminum profiles:

1.Ultimate tensile strength reaches at least 190 MPa (28,000 psi), which means the profiles can handle significant loads without breaking.

2.Yield strength is at least 160 MPa (23,000 psi), so the material resists permanent deformation even under heavy use.

3.Elongation rates of 8% or more for thinner sections and 10% for thicker ones, which allows the profiles to absorb impacts and flex without cracking.

4.Higher tensile and yield strength compared to T5 temper, making it better suited for demanding structural applications.

I rely on these properties to prevent fatigue and deformation, especially in industrial and architectural projects where safety and longevity matter most.

Corrosion resistance

I have seen how 6063-T6 alloy stands up to harsh environments. Its corrosion resistance protects my profiles from moisture, chemicals, and weathering. This means I can use them in outdoor structures, transportation, and even marine applications without worrying about rust or surface damage. The alloy’s composition, including magnesium and silicon, creates a natural oxide layer that shields the metal. This feature reduces maintenance costs and extends the life of every profile I install.

I also trust 6063-T6 because it meets strict industry standards for durability and corrosion resistance. Here are some of the key standards:

| Standard | Description |

| ASTM B361 | Standard for aluminum castings |

| ASTM B345 | Seamless aluminum pipe standard |

| ASTM B491 | Standard for aluminum alloy pipes |

| ASTM B429 | Aluminum pressure vessel standard |

| ASTM B483 | Rolled aluminum bar standard |

| ASTM B210 | Aluminum alloy bar standard |

| AA 6063 | AlMg0.7Si alloy composition |

| MIL G-18014 | Military standard for aluminum alloys |

| MIL W-85 | Military standard for aluminum welding |

| SAE J-454 | Automotive engineering standard for aluminum |

These certifications give me peace of mind that my materials will perform reliably in any application.

Quality control

Certifications

I know that quality starts with the right certifications. JIJU ALUMINIUM has earned several important certifications that prove their commitment to excellence. When I order custom profiles, I look for these marks of quality:

1.ISO 9001 for quality management, which ensures every process meets international standards.

2.AS 9100 for aerospace, showing the company can deliver parts for the most demanding industries.

3.ISO 14001 for environmental sustainability, which aligns with my values for responsible manufacturing.

4.ISO 50001 for energy efficiency, helping reduce the environmental impact of production.

5.SGS for independent product testing, which adds another layer of trust.

6.CE for European conformity, allowing me to use these profiles in projects across Europe.

7.RoHS for restricting hazardous substances, which is essential for electronics and green building projects.

These certifications assure me that every batch of profiles meets strict requirements for safety, performance, and sustainability.

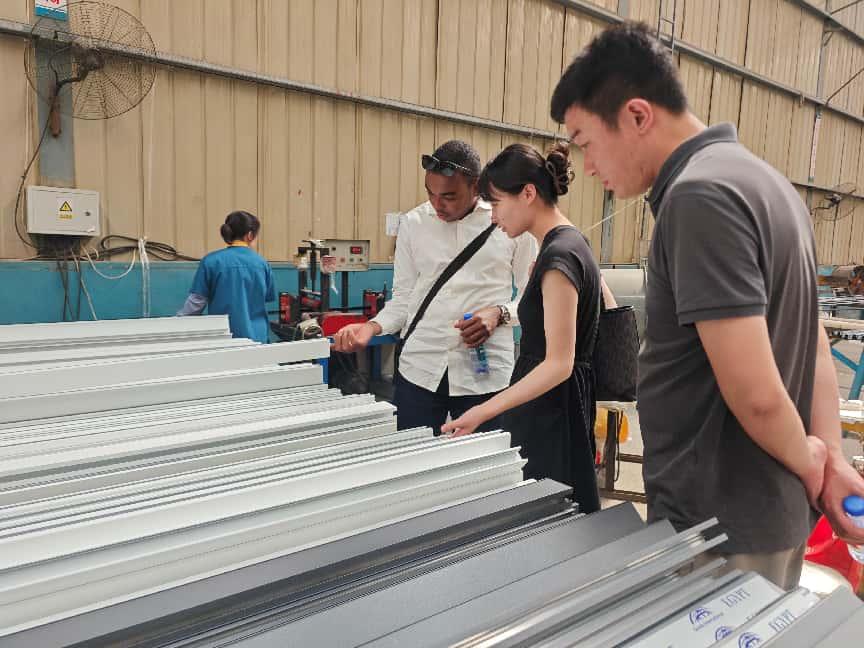

Inspection

I have visited JIJU ALUMINIUM’s facilities and seen their quality control in action. Their process covers every stage of production, from raw materials to final inspection. Here is how they maintain such high standards:

1.Raw material inspection checks every aluminum billet for chemical composition and surface defects before production begins.

2.Process monitoring and control track extrusion parameters like temperature and pressure in real time, ensuring consistency.

3.In-line quality checks use automated systems to spot defects immediately during extrusion.

4.Post-extrusion inspection measures dimensional accuracy and surface finish, so every profile matches my specifications.

5.Quality documentation and traceability keep detailed records of each step, making it easy to track and resolve any issues.

Note: High-grade materials and strict quality control are essential for industrial applications. I depend on these measures to deliver reliable, high-performance special-shaped aluminum profiles for every project.

Manufacturing techniques

Equipment

Extrusion machines

I have seen firsthand how JIJU ALUMINIUM invests in advanced extrusion machines. These machines form the backbone of our production process. With 12 extrusion lines ranging from 600 to 10,000 tons, I can handle projects of any size. The extrusion process shapes aluminum rods into precise profiles through hot melting. This method ensures that every profile meets strict dimensional requirements. Automation in these machines reduces labor needs and minimizes human errors. I trust the skilled operators to maintain safety and consistency throughout the process.

CNC centers

Precision matters to me, especially when working with special-shaped aluminum profiles. JIJU ALUMINIUM operates over 30 high-precision CNC machines. These centers allow me to achieve complex cuts and detailed finishes. Centralized processing saves time and simplifies procedures. I rely on CNC centers for deep processing, such as drilling, milling, and slotting. The combination of extrusion and CNC machining guarantees that my profiles fit perfectly in every application.

Note: The facility also includes anodic oxidation lines, electrophoretic coating lines, powder spraying, and wood grain production lines. These finishing options help me deliver profiles with enhanced durability and attractive appearances.

Production efficiency

Capacity

JIJU ALUMINIUM’s production capacity impresses me. The factory produces up to 60,000 tons of custom aluminum profiles each year. This high output means I never worry about delays, even on large-scale projects. Continuous operation and fully automated production lines increase efficiency and keep lead times short. I can place both small and large orders with confidence, knowing the team can deliver on time.

One-stop service

I appreciate the one-stop service that JIJU ALUMINIUM provides. From casting and extrusion to coloring and finishing, every step happens under one roof. Here is a quick overview of the main processes:

| Process | Description |

| Casting | Aluminum is melted and formed into rods. |

| Extrusion | Aluminum rods are shaped into profiles through hot melting. |

| Coloring | Finishing processes like oxidation and coating enhance quality and appearance. |

This integrated approach streamlines my workflow. I can communicate with a single team for all my needs, which reduces errors and saves time. The flexibility of the production system allows me to request custom finishes, textures, and colors for each project.

Tip: I often take advantage of the thermal insulation workshop and powder coating lines to meet specific project requirements. These features help me deliver energy-efficient and visually appealing solutions.

Lightweight and energy efficiency

Aluminum profiles from JIJU ALUMINIUM have transformed the way I approach construction and manufacturing projects. I always prioritize materials that offer both strength and efficiency. Aluminum stands out because it is much lighter than steel, yet it maintains impressive durability. This combination allows me to design structures that are easier to handle and install, while also supporting energy-saving goals.

Easy handling

Installation

I notice the difference as soon as I start working with JIJU ALUMINIUM’s special-shaped profiles. Their lightweight nature simplifies every step of the installation process. I do not need heavy lifting equipment, which speeds up assembly and reduces labor costs. The profiles arrive with accurate dimensions and pre-machined features, so I can assemble them directly without making on-site modifications. This precision saves me time and ensures that every component fits perfectly.

1.I can move and position profiles with minimal effort.

2.Installation teams work faster and safer, reducing the risk of injury.

3.Pre-machined holes and slots allow for direct assembly, eliminating extra steps.

Tip: When I use aluminum profiles, I often complete installations in half the time compared to traditional steel components. This efficiency helps me meet tight project deadlines and control costs.

Structural integrity

Despite their low weight, JIJU ALUMINIUM’s profiles never compromise on strength. I rely on high-grade alloys like 6063-T6, which provide a balance of flexibility and durability. Precision engineering ensures that each profile meets strict specifications. The design process uses advanced CAD systems to optimize material distribution, maximizing strength where it matters most.

1.Aluminum is about one-third the weight of steel, but high-grade alloys deliver comparable strength.

2.The 6000 series alloys, especially 6061 and 6063, offer excellent extrudability and structural performance.

3.Billets are prepared and heated to exact temperatures, preserving mechanical properties during extrusion.

I trust these profiles in demanding applications, from building frameworks to automotive parts. They maintain structural integrity even under heavy loads and harsh conditions.

| Advantage | Description |

| Lightweight | Aluminum profiles are significantly lighter than traditional materials like steel. |

| Strength-to-Weight Ratio | They offer an impressive strength-to-weight ratio, maintaining structural integrity. |

| Ideal for Weight-Sensitive Industries | Crucial for industries like automotive and aerospace, where reducing weight is essential. |

Energy efficiency

I see clear benefits in energy efficiency when I choose aluminum profiles. Their lightweight structure allows for more efficient shipping and handling, which reduces transportation emissions. Research shows that aluminum profiles can reduce weight by up to 40% compared to steel, making installation and logistics much easier. Lighter materials also lead to lower transportation costs and improved fuel efficiency, especially in vehicles and trailers.

1.Efficient shipping reduces energy consumption from planning to completion.

2.Lower weight means less fuel required for transport, aligning with modern environmental standards.

3.Reduced emissions help me meet sustainability goals for every project.

Using JIJU ALUMINIUM’s special-shaped profiles, I achieve both practical and environmental advantages. I deliver projects that are easier to build, more cost-effective, and better for the planet.

Customer service

Communication

Support teams

I always appreciate the dedicated support teams at JIJU ALUMINIUM. When I reach out with questions or special requests, I receive prompt responses from knowledgeable staff. The company assigns project managers who guide me through each stage, from initial inquiry to final delivery. These professionals understand the technical details of aluminum profiles and help me resolve any issues quickly. I rely on their expertise to keep my projects on track and ensure that my requirements are met.

1.I can contact support by phone, email, or online chat.

2.The team provides technical advice and troubleshooting.

3.I receive clear answers about product specifications and lead times.

Tip: I recommend discussing your project with their support team early. This helps clarify requirements and avoids misunderstandings later.

Updates

JIJU ALUMINIUM keeps me informed throughout the order process. The company uses a digital ordering system that provides real-time updates on production and shipping status. I log in to check the progress of my order at any time. This transparency gives me confidence and helps me plan my workflow. I receive notifications when my profiles enter production, finish processing, and ship out.

The logistics network at JIJU ALUMINIUM guarantees on-time delivery. I get regular updates on my order status, which allows me to coordinate installation teams and manage deadlines. For urgent orders, the company offers expedited delivery. I have used this service when I needed profiles quickly, and it always arrived on schedule.

Note: Timely updates and transparent communication make it easier for me to manage complex projects and avoid delays.

Order management

Flexibility

JIJU ALUMINIUM accommodates a wide range of order quantities and custom specifications. I have placed both large and small orders, depending on my project needs. The company offers flexible minimum order quantities for different products, which allows me to order exactly what I require. Here is a summary of their options:

| Product Description | Minimum Order Quantity |

| Professional Aluminum Profiles Surface Treatment and Deep Processing Custom Extrusions | 500 kilograms |

| Custom Aluminum Precision Stainless Steel Titanium Cnc Aluminum Extrusion for 3d Printer Machining Milling Turning Parts | 500 kilograms |

| Customize Extrusion 6063 Aluminum Profile Extrusion for Doors and Windows Perfiles De Aluminio Anodized Aluminum Profile | 100 kilograms |

| Custom Extruded Aluminum Sun Shade Profiles | 100 pieces |

I find this flexibility especially useful for prototypes, small-batch production, and large-scale installations. The company adapts to my requirements, whether I need a few specialized profiles or a bulk shipment for a major project.

Pre-sales and after-sales

I value the comprehensive service that JIJU ALUMINIUM provides before and after the sale. During pre-sales, the team helps me select the right alloy, finish, and dimensions for my application. They offer samples and technical drawings so I can review options before committing. After the sale, I receive ongoing support for installation, maintenance, and troubleshooting. If I encounter any issues, the company responds quickly and resolves them efficiently.

1.Pre-sales consultations help me make informed decisions.

2.After-sales support ensures long-term satisfaction.

3.The team follows up to confirm that my profiles meet expectations.

Block Quote: “JIJU ALUMINIUM’s customer service gives me peace of mind. I know I can rely on their support from start to finish, no matter how complex my project.”

Applications and case studies

Construction

I have seen the impact of JIJU ALUMINIUM’s special-shaped profiles in the construction industry. These profiles help me achieve both structural strength and visual appeal in my projects. I often use them for custom architectural features that require precision and durability. The flexibility of aluminum allows me to design unique solutions for modern buildings.

Some of the most common applications I rely on include:

1.Handrails for stairs that combine safety with a sleek appearance.

2.Borders with screw attachments, which make installation fast and secure.

3.Special U profiles that add aesthetic value to facades and interiors.

These components not only enhance the look of a building but also improve its functionality. I appreciate how easy it is to integrate these profiles into both new constructions and renovation projects. The corrosion resistance of aluminum ensures that these elements maintain their quality over time, even in challenging environments.

Transportation

In the transportation sector, I have witnessed a shift toward lightweight materials. JIJU ALUMINIUM’s custom profiles play a crucial role in this transformation. I choose aluminum for its strength, low weight, and resistance to harsh conditions. These qualities help me deliver solutions that meet strict industry standards.

| Application Area | Benefits |

| Automotive | Lightweight, improves fuel efficiency, reduces carbon emissions |

| Aerospace | Reduces jet fuel expenses, lightweight design |

| Marine | Durable and weather-resistant components |

| Military | Strong yet lightweight materials for various applications |

I have noticed that automakers now use aluminum instead of steel to reduce vehicle weight. A 15% reduction in weight can lead to up to 20% less fuel usage. In aerospace, up to 80% of commercial airplanes use aluminum, which significantly lowers jet fuel costs. I value the versatility of aluminum, as it can be shaped through extrusion, rolling, or casting. Its durability ensures long-lasting performance, even in marine and military applications.

Tip: Aluminum profiles can be up to 40% lighter than steel, making them ideal for transportation projects where every kilogram counts.

New energy

I have participated in several new energy projects where aluminum profiles make a real difference. In solar energy systems, I use these profiles to create durable frames for solar panels. The strength and corrosion resistance of aluminum ensure that the frames last for years, even when exposed to the elements. This durability contributes to the overall energy efficiency of the system.

1.Aluminum frames support solar panels and protect them from wind and weather.

2.The lightweight nature of aluminum makes installation easier and reduces structural load.

3.Long-lasting frames help maximize the return on investment for solar projects.

I trust JIJU ALUMINIUM’s special-shaped profiles to deliver reliable performance in every new energy application. Their custom solutions help me meet the demands of a rapidly evolving industry.

Electronics

I have seen how special-shaped aluminum profiles from JIJU ALUMINIUM transform the electronics industry. I often choose these profiles for their excellent heat dissipation and lightweight properties. Aluminum’s natural conductivity helps manage heat in devices like LED lighting, power supplies, and communication equipment. I rely on custom extrusions to create housings and frames that protect sensitive components.

I appreciate the precision that JIJU ALUMINIUM delivers. Their CNC machining allows me to specify tight tolerances for connectors, slots, and mounting points. This accuracy ensures that every electronic enclosure fits perfectly and provides reliable protection. I have used their profiles in server racks, control panels, and even consumer electronics like audio amplifiers.

Tip: I recommend using anodized finishes for electronic profiles. This surface treatment improves corrosion resistance and adds an extra layer of insulation, which is crucial for safety in electrical applications.

Here are some common uses I have seen in electronics:

1.Heat sinks for LED modules and power transistors

2.Enclosures for routers, modems, and industrial controllers

3.Frames for display panels and touchscreens

4.Mounting rails for circuit boards

I trust JIJU ALUMINIUM to deliver profiles that meet strict industry standards for safety and performance.

Furniture

I have worked on many furniture projects where aluminum profiles make a real difference. I prefer aluminum for its modern look, light weight, and strength. JIJU ALUMINIUM offers a wide range of finishes, so I can match any design style. I often select powder-coated or wood grain finishes to create unique pieces.

Aluminum profiles help me design furniture that is both functional and attractive. I use them for table frames, chair legs, shelving units, and cabinet doors. The profiles resist scratches and stains, which keeps furniture looking new for years. I also value the ease of assembly. Pre-drilled holes and custom connectors allow me to build and install furniture quickly.

| Furniture Application | Benefits |

| Table frames | Lightweight, strong, modern look |

| Chair legs | Durable, corrosion-resistant |

| Shelving units | Easy to assemble, customizable |

| Cabinet doors | Sleek, scratch-resistant |

Note: Aluminum furniture profiles are recyclable. I can promote sustainability in my projects by choosing these materials.

Industry

I have seen JIJU ALUMINIUM’s special-shaped profiles excel in industrial settings. I rely on their strength and versatility for machine frames, conveyor systems, and protective barriers. The profiles withstand heavy loads and harsh environments, which is essential for factories and workshops.

I often specify custom extrusions for automation equipment. The flexibility of aluminum lets me design frames that support motors, sensors, and control panels. I can add slots and grooves for easy mounting of accessories. This modular approach speeds up installation and reduces downtime during maintenance.

1.Machine guards and safety enclosures

2.Workbenches and assembly lines

3.Storage racks and material handling systems

I trust JIJU ALUMINIUM’s quality control. Their profiles meet international standards and pass rigorous inspections. I know I can depend on their products for reliable, long-term performance in demanding industrial applications.

Medical

I have seen the medical industry demand the highest standards for materials and precision. JIJU ALUMINIUM’s special-shaped aluminum profiles help me meet these strict requirements. I often choose aluminum for medical equipment because it offers a unique combination of strength, light weight, and corrosion resistance. These qualities make it ideal for environments where hygiene and reliability matter most.

I use custom aluminum profiles in a variety of medical devices and hospital infrastructure. For example, I specify these profiles for the frames of hospital beds. The light weight allows staff to move beds easily, while the strength ensures patient safety. I also rely on aluminum for the construction of medical carts and trolleys. These carts must withstand frequent cleaning and constant movement. Aluminum’s natural oxide layer protects against disinfectants and moisture, so the carts last longer and look new even after years of use.

In diagnostic equipment, I require precise and stable frames. JIJU ALUMINIUM’s CNC machining delivers the tight tolerances I need for imaging machines and laboratory analyzers. I can request custom slots and mounting points for sensors, screens, and control panels. This flexibility helps me design equipment that fits the unique needs of each medical facility.

Note: I always recommend anodized or powder-coated finishes for medical profiles. These finishes improve resistance to bacteria and make cleaning easier. They also add an extra layer of protection against scratches and chemicals.

Here are some common medical applications where I use JIJU ALUMINIUM’s special-shaped profiles:

1.Hospital bed frames and side rails

2.IV stands and infusion pump supports

3.Wheelchair frames and mobility aids

4.Medical instrument enclosures

5.Cleanroom partitions and modular walls

6.Operating room lighting fixtures

I trust JIJU ALUMINIUM to deliver profiles that meet international medical standards. Their quality control ensures every batch is free from defects and safe for use in sensitive environments. I have worked with their team to develop custom solutions for specialized equipment, such as adjustable examination tables and surgical carts. The ability to customize every detail, from shape to surface finish, gives me confidence that my designs will perform reliably in hospitals and clinics.

Tip: When I design for the medical field, I always prioritize safety, hygiene, and durability. JIJU ALUMINIUM’s expertise in custom profiles helps me achieve these goals with every project.

I trust JIJU ALUMINIUM because they deliver quality, customization, and service that drive project success. Their strict inspections, clear communication, and one-stop service make every step smooth.

| Advantage | Impact on My Projects |

| Quality Assurance | Reliable materials and consistent results |

| Customer Support | Fast responses and technical guidance |

| After-Sales Service | Ongoing help and quick problem resolution |

I choose JIJU ALUMINIUM for these reasons:

1.Design flexibility for complex shapes

2.Rapid prototyping for faster results

3.Versatile, lightweight, and corrosion-resistant profiles

I recommend reaching out to their team for a consultation or quote.

FAQ

What is a special-shaped aluminum profile?

I define special-shaped aluminum profiles as custom extrusions with unique cross-sections. These profiles do not follow standard shapes. I use them when my project requires specific dimensions or functions that standard profiles cannot provide.

How do I start a custom order with JIJU ALUMINIUM?

I contact their support team with my design or idea. They review my requirements, suggest improvements, and provide a quote. I approve the design, and they begin mold development and production.

What industries benefit most from these profiles?

I have supplied profiles to construction, transportation, electronics, new energy, furniture, industry, and medical sectors. Each industry values the lightweight, strength, and corrosion resistance that these profiles offer.

How long does it take to produce a custom profile?

Production time depends on complexity and order size. I usually receive samples within 7–15 days after confirming the design. Full production takes 15–30 days.

Can I request small batch or prototype orders?

Yes, I often order small batches or prototypes for testing. JIJU ALUMINIUM accepts low minimum order quantities, which helps me validate designs before large-scale production.

What surface finishes are available?

I choose from anodizing, powder coating, electrophoresis, and wood grain finishes. Each finish offers different benefits for appearance and durability. The support team helps me select the best option for my application.

How does JIJU ALUMINIUM ensure quality?

I trust their strict quality control. They inspect raw materials, monitor production, and check finished profiles. Certifications like ISO 9001 and SGS give me confidence in every batch.

Are JIJU ALUMINIUM’s profiles environmentally friendly?

Yes, I select aluminum because it is recyclable and energy-efficient. JIJU ALUMINIUM follows ISO 14001 standards for environmental management. I support sustainable projects by choosing their products.