Extrusion process

Aluminum extrusion (or aluminum extrusion molding) is defined as the aluminum billet placed in the die cavity (or extrusion cylinder) to apply strong pressure, forcing the aluminum billet to produce directional plastic deformation, extrusion from the extrusion die holes, so as to obtain the required cross-section shape, size and mechanical properties of the parts or semi-finished products of the plastic processing methods. Its working principle is similar to “squeezing toothpaste”. This metal molding method has the following significant advantages.

1.Long-lasting

Aluminum’s resistance to corrosion, erosion and weathering is one of its most significant advantages. Aluminum naturally rusts and resists corrosion without additional treatment. This is due to the presence of a thin, naturally occurring protective film of aluminum oxide on its surface. By anodizing, its resistance to corrosion becomes even stronger. For example, in outdoor environments, anodizing can be performed to 25 microns, which increases corrosion resistance and improves surface finish. In addition, aluminum requires no maintenance and in most cases can be used without fear of corrosion.

2.lightweight and sturdy

Aluminum is over 33% lighter than steel while retaining most of its strength. Most aluminum alloys have a tensile strength range of about 70-700 MPa and are two-thirds less dense than steel. Product design engineers don’t have to worry about the strength of extruded aluminum parts, and it can be used as a structural component in the construction industry as well as in the automotive industry, making it an excellent alternative to other metal materials. The automotive industry is making significant use of aluminum alloys in order to lighten weight and reduce energy consumption.

3.Good thermal conductivity

Aluminum has very similar thermal conductivity to copper, but is much lighter in weight. Aluminum is an excellent conductor of heat, and the contours of the aluminum extrusion are designed to maximize the surface area for thermal conductivity and the formation of thermal pathways. A typical example is a computer CPU cooler, where aluminum is used to carry heat away from the CPU.

4.Stylish appearance

Extruded aluminum can be painted, plated, polished, and anodized, giving engineers a wider range of appearance options than other materials.

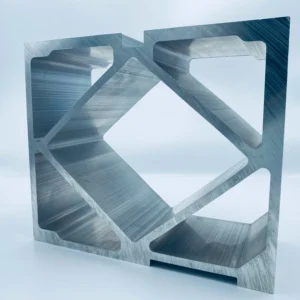

5.Wide range of applications

Basically any cross-section shape can be formed by aluminum extrusion, so aluminum extrusion has a wide range of applications and engineers can design different cross sections to meet the requirements of different application environments.

6.Convenient for secondary processing

Aluminum extrusions can be easily formed, cut, drilled, machined, stamped, bent and welded to suit specific purposes.

7.Short cycle time and low cost for mold processing

Aluminum extrusion has simple tooling and short, inexpensive processing cycles. This is AEC’s comparison of aluminum extrusion and other metal forming processes for reference only.

8.Shock and deformation absorption

In construction, aluminum extrusions resist deformation caused by weather and building movement. In transportation, they absorb impact energy. Aluminum extrusions maintain strength and flexibility under load and rebound from impact.

9.Environmentally friendly

Aluminum is an environmentally friendly material, easy to recycle. In short, aluminum is the metal of the future with its irreplaceable advantages. It is not only environmentally friendly, lightweight, naturally corrosion-resistant and strong, but also conducts heat and electricity well.

Extruder construction

1.Extruder structure of the main three major parts

The extruder structure is mainly composed of three main parts: mechanical part, hydraulic part and electrical part. The mechanical part consists of base, pre-stressed frame tension column, front beam, movable beam, X-type guided extrusion cylinder seat, extrusion shaft, ingot supplying mechanism, residue separation shear, sliding die holder and so on. Hydraulic system mainly consists of main cylinder, side cylinder, locking cylinder, piercing cylinder, large-capacity axial piston variable pump, electro-hydraulic ratio servo valve (or electro-hydraulic proportional control valve), position sensor, oil pipe, oil tank and various hydraulic switches. The electrical part is mainly composed of power supply cabinet, operation desk, PLC programmable controller, upper industrial control machine and display screen.

2.Extruders are categorized into single-acting and double-acting extruders according to their structure

The single-action aluminum extruder extrudes by advancing the main cylinder and pressing the aluminum bar toward the die through the extrusion cake, thus forming the shape. The round tubes extruded by single-action extruder have seams, which can only be detected with instruments. Double-action extruder, hydraulic oil through the filling valve to fill the main hydraulic cylinder, pushing the main plunger forward ( the front of the main plunger is connected to the moving beam, moving beam mounted on the extrusion shaft ), to realize the extrusion action . The main plunger is also the perforating cylinder. When piercing, the piercing plunger moves forward (the piercing needle is installed at the front end) to realize the piercing action. Since the main plunger and perforating plunger can operate independently of each other, they are two actions, so they are called double-action extruders.

3.According to the form of extrusion, it is divided into forward extruder, reverse extruder and forward and reverse extruder

Forward extrusion is relatively simple and corresponds to the direct transfer of the extrusion force to the billet. The direction of metal flow is the same as the direction of advancement of the extrusion rod, which is the basic characteristic of this extrusion method. Compared with forward extrusion, thanks to the special material flow characteristics of reverse extrusion (no friction between the bar and the inner wall of the extrusion cylinder), the material flow is more homogeneous, so the extrusion speed is faster, because the bar tends to be longer, so the pressure balance is thinner, which means higher production efficiency. At the same time, reverse extrusion products along the longitudinal direction of the temperature rise is very small, the average temperature is also low, in product quality can ensure good dimensional accuracy. Reverse extrusion and its short-stroke design can be equipped with or without a piercing device. Therefore, reverse extrusion is currently the most efficient form of extrusion for pipe and bar production.

Extruder Selection

(1) Choose according to the characteristics of the extruded alloy. For example, extruding 6063-T5 industrial aluminum profiles, you can choose positive single-action horizontal extruder; extruding soft alloy tubes, you can choose positive double-action horizontal extruder.

(2) In the production of high-precision industrial profiles, the choice of high-performance, low-consumption, high-efficiency automated extruder. For example, the industry’s mainstream short-stroke, high-speed front loading extruder, has many advantages. For example, the stacked tensioning post / outer sleeve design and the finite element optimized machine body ensure a longer service life. At the same time, the main components such as the front beam, the extrusion cylinder and the master cylinder have a higher frame rigidity. The front loading ensures that the barrel can be loaded by moving it forward with no friction between the bar and the barrel, and the symmetrical upsetting improves the venting effect of the barrel.

(3) Selection according to the specific extrusion capacity. The size of the extrusion capacity should be calculated, according to their own production conditions, technical level, equipment conditions and sales conditions as the basis for calculating the annual production time, the amount of work per hour and other parameters to calculate the annual production capacity of the extruder, because the size of the output and the size of the cross-section to determine the choice of which extruder, different alloy compositions required for the extrusion capacity is also not the same, the extrusion pressure of the ordinary aluminum extruder is 250MPa ~ 400MPa, the extrusion pressure is 250MPa ~ 400MPa, the extrusion pressure is 250MPa ~ 400MPa. The extrusion pressure required for ordinary aluminum profiles is 250MPa~400MPa, the extrusion pressure required for hollow aluminum profiles is 450MPa~1000MPa, and the extrusion pressure required for pure aluminum extrusion is smaller, 150MPa~250MPa. The extrusion methods are also very different, and the extrusion pressure required for forward extrusion is 1/3 larger than that required for reverse extrusion.

(4) According to the actual financial situation of the user and product positioning to choose. If the enterprise production of aluminum products for low-grade, you can choose domestic extruder; if it is positioned as a high-grade products, we must choose to import the extruder. Regardless of which grade of extruder, according to their own actual conditions to determine, if only the production of low-grade aluminum products, there is no need to choose foreign imports of extruders, on the one hand, the amount of investment is larger, on the other hand, for the maintenance of the later is also a very difficult thing, after all, all aspects of the cost will be increased, but also affects the progress of the production, to be able to live within their means, all-round considerations.

(5) in accordance with the manufacturer’s pre-planning and design, as far as possible, the use of standard equipment, equipment to save space, personnel savings, shorten the preparation cycle of production technology. For example, you can choose a new type of compact extruder, this new concept will be forged front beam of the extruder installed at one end of the extruder, the other end is forged main column cylinder, equipped with a balancing tank, to achieve a new hydraulic concept. With this concept, the position of the main tank becomes more flexible, thus making it unnecessary to mount it above the rear beam. This construction optimizes the geometry of the cast frame, resulting in a very compact extruder structure.

(6) Whether the extrusion press manufacturer can provide colleges and universities, strong technical support, staff training, technical support, so that the customer in the latter part of the production of smooth and worry-free. Strong after-sales service network is also a top priority when choosing, only perfect after-sales service, is a strong backing for manufacturing.

Future Technology Trends

1. Further increase in equipment squeezing force

When equipment has more extrusion force, it means further breakthroughs in the limitations of the current aluminum extrusion process, which opens up a wider world for the creation of new aluminum products and even the manufacture of new materials. In addition, higher extrusion pressures result in more efficient extrusion cycles, which in turn increase the existing capacity and mean better economy. In order to achieve this, the rigidity and structural design of the extruder frame needs to be continuously improved to withstand the stronger extrusion pre-stress. The latest technology from overseas is the 160 MN extruder from SMS, which uses a CF frame that is not only compact, but also optimizes the geometry of the cast frame, thus significantly improving the frame structure and component stiffness of the machine. In addition, the machine utilizes laminated tensioning columns (with external pressure sleeve), a cascade design that provides a lower notch factor than conventional screw-retained tensioning columns. At the same time, precise adjustment by means of separate hydraulic cylinders achieves greater stiffness and pre-stress handling. This design offers many advantages such as no wear, long life, no adjustments, low friction, very high impact resistance (overload), etc.

2.Energy and Operational Efficiency

(1) Energy efficiency. In order to further improve the economy, the optimization of energy-saving technologies for each part of the extrusion equipment will be the key in the future. The following is only an example of energy saving in the pumping station of the extruder. For example, the Italian company Danieli relies on its self-developed ESED4.0 intelligent pumping station energy-saving system, which has become the most advanced energy-saving management program in the industry. The system through the quantitative pump with variable frequency drive technology, so that during the extrusion process, only the required number of pumps to start, and then realize the precise control and the number of working pumps ratios, which will only open the number of hydraulic pumps required in the current extrusion speed, thus reducing the additional and unnecessary report of the pump group loss. At the same time, the system offers significant efficiency gains, such as a 30% increase in pump displacement through variable frequency drive of the dosing pumps. In short, the system’s economy can be reflected in the following two aspects: (1) investment: 10% reduction in hydraulic costs, 20% reduction in piping, the main pump low noise. ②Operation: Reduced overall maintenance costs and shorter non-extrusion cycle.

(2) Improvement of operation efficiency and more intelligent equipment operation. In terms of the theme of creating economical equipment, we will have to consider further improving the operating efficiency of the extruder in the future.