Aluminum Processing Industry Overview

According to the different processing techniques, aluminum processing products can be divided into two major categories;

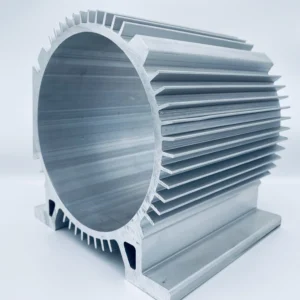

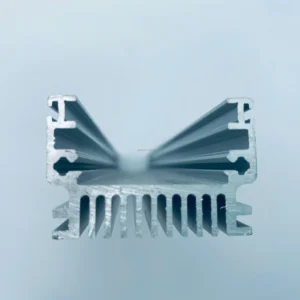

One is the use of fusion casting – extrusion process production of aluminum profiles:

Aluminum rods extruded into aluminum profiles using the hot extrusion process; hot extrusion is the earliest of several extrusion processes used in the extrusion molding technology, it is in the hot forging temperature with the help of the material plasticity good characteristics of the metal for a variety of extrusion molding. At present, hot extrusion is mainly used in the manufacture of ordinary cross-section of long parts, profiles, tubes, bars and various machine parts. Hot extrusion can not only form good plasticity, relatively low strength of non-ferrous metals and their alloys, low, medium carbon steel, etc., but also can be formed into high strength high carbon, high alloy steel, such as structural special, stainless steel, high-speed tool steel and heat-resistant steel, etc.. As the billet must be heated to hot forging temperature for extrusion, often accompanied by more serious oxidation and decarburization and other heating defects, affecting the dimensional accuracy and surface roughness of the extruded parts. In general, machine parts hot extrusion molding, and then use cutting and other machining to improve the dimensional accuracy and surface quality of the parts.

Melting process flow:

Furnace loading → melting → stirring complete melting → add scrap → melting → add scrap → complete melting → sprinkle covering agent and slagging agent → slagging → stirring → sampling, pre-furnace analysis → add Al-Si (Sl-Cu, Cr additives), Mg ingot → stirring → sampling, post-furnace analysis → composition adjustment → refining → slagging re-covering → resting

The other is aluminum sheet and strip and aluminum foil produced using the hot rolling – cold rolling process. Among them, aluminum profiles are mainly used in construction and industrial fields, while aluminum sheet and foil are mainly used in home appliances, food and beverage, and battery fields:

Continuous casting slab or initial rolling slab as raw material, heated by a step heating furnace, high-pressure water dephosphorization into the roughing mill, roughing material by cutting the head, tail, and then into the finishing mill, the implementation of computer-controlled rolling, final rolling that is, after laminar cooling (computer-controlled cooling rate) and coiling machine coiling, become straight hair rolls. The head and tail of the straight hair coil is often tongue and fishtail shape, thickness, width accuracy is poor, there are often wave-shaped edge, folded edge, tower and other defects. Its volume weight is heavy, the inner diameter of the steel coil is 760mm. (General pipe making industry like to use.) The straight hair coil by cutting head, tail, cutting edge and more than one straightening, leveling and other finishing line processing, and then cut plate or re-roll, that is to become: hot rolled aluminum plate, flat hot rolled aluminum coil, longitudinal cut strip and other products. If the hot rolled finishing coils are pickled to remove oxidized skin and coated with oil, they will become hot rolled pickled coils.

With hot rolled aluminum coil as raw material, after pickling to remove the oxide skin for cold rolling, the finished product is rolled hard coil, due to continuous cold deformation caused by cold hardening of rolled hard coil strength, hardness, toughness and plastic index decline, stamping performance deterioration, can only be used for simple deformation of the parts. Rolled hard coil can be used as raw materials for hot-dip galvanizing plant, because the hot-dip galvanizing unit are set with annealing line. Rolled hard coil weight is generally 6 ~ 13.5 tons, aluminum coil inner diameter of 610mm. general cold rolled plate, coil should be continuous annealing (CAPL unit) or hood furnace for de-annealing treatment to eliminate cold hardening and rolling stress, to achieve the mechanical properties specified in the standard index. Cold rolled aluminum plate surface quality, appearance, dimensional accuracy are better than hot rolled plate.

Industry chain analysis: the main products in the midstream for aluminum profiles and aluminum sheet and foil

Aluminum processing industry chain is directly upstream of the production of electrolytic aluminum and renewable aluminum industry, at present, China’s renewable aluminum industry, although the development of faster, but still lagging far behind the developed countries, in the context of the global carbon neutrality, renewable aluminum may usher in the policy support; industry chain for the production of processed aluminum products in the middle of the industry chain, the products are mainly for the aluminum extrusion and aluminum sheet with foil; products downstream of the application of processed aluminum products in the fields of construction and decoration, packaging containers, aerospace, transportation and so on. Decoration, packaging containers, aerospace, transportation and so on.

China’s national economy and high-tech stable, sustained and rapid development, prompting China’s aluminum smelting and aluminum profile processing industry is developing very rapidly. China’s aluminum aluminum alloy profile industrial aluminum profile production in 2006 has reached 8.793 million tons, more than the United States to become the world’s first; 2007 production of up to 12.508 million tons, an increase of 42.45% compared with 2006, hitting a new record high; 2007 imports of 690,000 tons of industrial aluminum, an increase of 0.6% compared with 2006; exports of 1.853 million tons of industrial aluminum profile, an increase of 49.3% compared with 2006 million tons, an increase of 49.5% over 2006, the net export of aluminum alloy profiles 1.163 million tons; in 2007, China’s apparent consumption of industrial aluminum 11.345 million tons. In January-June 2008, China’s aluminum industry production, alumina production of 11.129 million tons, an increase of 7.1% over the same period in 2007, is expected to 2008 annual production of 23 million tons; electrolytic aluminum production of 6.620 million tons, an increase of 12.9% over the same period in 2007, it is expected that the annual production of 2008 will reach 14.5 million tons; aluminum processing material 6.879 million tons, an increase of 38.3% over the same period in 2007; aluminum alloy profiles net exports of 1.163 million tons. the same period of 2007, an increase of 38.3%, is expected to 2008 annual output will reach 14 million tons.

Since the reform and opening up, especially since the new century, China’s non-ferrous metal industry continues to develop rapidly, has become the world’s largest producer and consumer of non-ferrous metals, the overall strength of the industry has been significantly enhanced, and the influence of the same industry in the international arena is increasing. The main performance: the total output and consumption continue to grow rapidly, in 2008, the total output of ten kinds of non-ferrous metals 25.2 million tons, for seven consecutive years ranked first in the world, of which copper production and consumption accounted for 20% and 24% of the world; electrolytic aluminum, lead, zinc production and consumption accounted for more than 30% of the world’s total. Economic benefits have been greatly improved. In 2008, enterprises above designated size are expected to realize sales revenues of more than 2.1 trillion yuan, and profits of more than 80 billion yuan. The pace of optimization and upgrading of industrial structure has been accelerated, and backward self-baking aluminum electrolytic tanks were all eliminated in 2005; at present, the capacity of advanced smelting technology for copper, lead and zinc accounts for more than 85% of the total production capacity; and the processing capacity of copper and aluminum has been greatly improved. The capability of independent innovation has been significantly enhanced, and the 350 kA and 400 kA large-scale prebaked electrolytic cell technologies developed independently with independent intellectual property rights are at the advanced level of the world’s aluminum industry and have been exported abroad; high-precision copper tubes with internal threads, high-grade aluminum alloy architectural profiles, and aluminum materials for high-speed trains with a speed of 350 km/h not only meet the domestic demand, but also have been exported to a large number of developed countries and regions. A new round of mineral search in domestic mines and the development of overseas mineral resources has made breakthrough progress, and the effectiveness of the search for minerals in the margins and depths of the existing nine major mining areas has been remarkable; a number of large-scale enterprise groups with strength have made substantial steps in overseas resource development and the acquisition and reorganization of overseas mining enterprises, which has effectively strengthened the ability to safeguard mineral resources.

Industry History: New Growth Points in the Industry

Since 1954, China’s aluminum processing industry officially started, although a late start, but rapid development, aluminum processing products production increased year by year. 2001, China’s electrolytic aluminum production capacity for the first time exceeded the United States, as of now, China has become the world’s highest production capacity of the aluminum industry in the world. 2020, the new energy automobile industry outbreak, the battery energy density enhancement rate is still not enough to meet the market demand, the quality and strength of the aluminum-based materials have been recognized by the market. The quality and strength of aluminum-based materials have to be recognized by the market, lightweight demand led to a new growth point in the aluminum processing industry.

Aluminum and its alloys are suitable for metal matrix composite material matrix, aluminum matrix composite material reinforcement can be continuous fiber, can also be short fiber, can also be from the spherical to irregular shape of the particles. Aluminum matrix composite reinforcing particles are SiC, AL2O3, BN, etc. Intermetallic compounds such as Ni-Al, Fe-Al and Ti-Al are also used as reinforcing particles.

Composites can be divided into three categories: polymer matrix composites (PMCs), metal matrix composites (MMCs), and ceramic matrix composites (CMCs). Metal matrix composites matrix is mainly aluminum, nickel, magnesium, titanium and so on. Aluminum has many characteristics in the production of composite materials, such as light weight, low density, good plasticity, aluminum-based composite technology is easy to master, easy to process. In addition, aluminum composite material has high specific strength and stiffness, good high temperature performance, more fatigue and wear-resistant, good damping performance, low coefficient of thermal expansion. Like other composite materials, it can combine specific mechanical and physical properties to meet the needs of products. Therefore, aluminum matrix composites have become one of the most commonly used and important materials in metal matrix composites. According to the different reinforcement, aluminum matrix composites can be divided into fiber reinforced aluminum matrix composites and particle reinforced aluminum matrix composites. Fiber-reinforced aluminum matrix composites have a series of excellent properties such as high specific strength, high specific modulus, good dimensional stability, etc. However, they are expensive and are mainly used in the field of aerospace, as the structural materials of space shuttle, artificial satellite and space station. Particle reinforced aluminum matrix composites can be used to manufacture satellites and aerospace structural materials, aircraft parts, metal mirror optical systems, automotive parts; in addition can also be used to manufacture microwave circuit plug-ins, inertial navigation systems, precision parts, turbocharged propellers, electronic packaging devices.

Industry Policy Background: Recycled Aluminum Gets Attention

In order to reduce carbon emissions from the aluminum processing industry and meet the demand for lightweighting in the downstream industry, numerous important policy documents released in recent years have mentioned the establishment of technical R&D support and industry planning for the aluminum processing industry. For example, the “Guiding Opinions on Comprehensive Utilization of Bulk Solid Waste in the 14th Five-Year Plan” issued in March 2021 encourages the recovery of iron, alkali and alumina from red mud, the recovery of valuable components such as rare and sparse metals and rare and precious metals from smelting slag, the enhancement of the efficiency of the utilization of mineral resources, the safeguarding of the security of the country’s resources, and the gradual increase in the comprehensive utilization rate of smelting slag. Utilization rate of smelting slag.

Current status of industry development

1.China’s aluminum production hit a new high

In 2017-2021, China’s aluminum production was first reduced and then increased. 2017 production reached the highest value before 2021, 58,324,400 tons, an increase of 0.63%; in 2018, China’s aluminum industry deepened the supply-side structural reform, strict control of new production capacity of electrolytic aluminum, and promote the exchange of electrolytic aluminum production capacity; at the same time by the impact of the impact of trade friction, the cost of production Continuously improving, China’s aluminum production fell sharply, down 21.91%; in 2019 and 2020, aluminum production improved, and in 2020, the output reached 57.793 million tons, an increase of 10.03% year-on-year; in 2021, aluminum production was further improved, reaching 61.052 million tons, the highest value in history.

2.Highest proportion of aluminum extrusion

According to the statistics of China’s total output of aluminum fabricated materials and the output of subdivided varieties in 2021, the comprehensive output of China’s aluminum fabricated materials was 44.7 million tons in 2021. Among them, the output of aluminum sheet and strip (including aluminum foil gross) is 13.35 million tons, accounting for 29.87%; the output of aluminum foil is 4.55 million tons, accounting for 10.18%; the output of aluminum extrusion is 22.02 million tons, accounting for 49.26%; the output of aluminum wire rod is 4.4 million tons; the output of aluminum powder is 0.16 million tons; and the output of aluminum forgings and others is 0.22 million tons.

3.Battery aluminum foil stands on the wind

From 2017 to 2021, the production of battery aluminum foil is on a growing trend. Affected by the long cycle of new production lines and the high impact of process difficulty, battery aluminum foil expansion is more difficult, in 2020, affected by the outbreak of the new energy automobile industry, the demand for battery aluminum foil industry in 2020 grew faster, and 2021 ushered in the release of battery aluminum foil production reached 140,000 tons, a year-on-year increase of double.

Industry Competitive Landscape

1. Regional competition: Shandong Province has the highest number

From the point of view of the regional distribution of China’s aluminum processing industry chain enterprises, the province with the largest number of aluminum processing industry chain enterprises is Shandong Province, followed by aluminum processing enterprises mainly distributed in the eastern region, and relatively few in the western region. There are many ports in the eastern region, which is convenient for export, at the same time, the eastern region has convenient transportation, and the downstream market is more developed, and the distribution of aluminum processing enterprises in the eastern region can help reduce transportation costs and form industrial clusters.

2.Enterprise competition: the first echelon production more than 1 million tons

Aluminum processing industry has a large number of enterprises, and the production of the head enterprise is relatively higher. From the perspective of the 2021 production situation of aluminum processing enterprises, it is mainly divided into three competitive echelons: the first echelon’s production exceeds 1 million tons.

Industry Development Prospects and Trends

1. Production is expected to exceed 100 million tons in 2027

Despite the increased environmental pressure, low-carbon requirements on aluminum production to form a suppressive effect, but the “14th Five-Year Plan” period, the new energy automotive industry into the sales surge period, at the same time, electronic consumer products in the 5G and chip technology continues to innovate under the influence of the iterative cycle to shorten the demand for aluminum products, aluminum production is expected to be in 2027 More than 100 million tons.

2.The future of China’s aluminum processing industry award facing industrial upgrading and transfer

The core of the upgrading of the aluminum processing industry should be to change the development mode to ensure the sustainable development of the industry. The specific embodiment of the transformation of the development mode should be the adjustment of production capacity, the rational layout of the industry, product structure adjustment, the use of applicable technology routes, etc., to promote the optimization and upgrading of the industrial structure.