I have seen firsthand how aluminum profiles for doors and Windows transform modern construction. These profiles offer a lightweight yet strong solution for both residential and commercial buildings. Their corrosion resistance ensures long-lasting performance, even in humid or coastal environments. My clients appreciate the flexibility in design, allowing for slim frames and large glass panels that bring in natural light. The demand for these profiles continues to grow, reflecting their reliability and adaptability.

Curtain Walls

Curtain walls require materials that balance strength, weight, and aesthetics. I use aluminum profiles to create sleek, durable facades for high-rise buildings and commercial complexes. These systems resist wind, rain, and temperature changes, protecting interiors while maintaining a modern appearance. My experience shows that architects and builders prefer aluminum for its ease of fabrication and installation. The profiles support energy-efficient glazing, helping projects meet sustainability goals.

Note: In 2023, the building and construction sector held 36.51% of the global aluminum profile market, highlighting the importance of these applications.

Transportation

Automotive

I work with automotive manufacturers who rely on aluminum profiles for lightweight, fuel-efficient vehicles. High-strength alloys and advanced extrusion techniques allow me to produce components like body panels, frames, and crash structures. These parts reduce vehicle weight, improving fuel economy and safety. I use CAD technology to optimize each profile for durability and performance. Industry leaders such as Constellium and Novelis have invested in new lines to meet the growing demand for aluminum auto parts, especially for electric vehicles.

1.High-strength aluminum alloys improve tensile strength and fatigue life.

2.Integration with carbon fiber and steel enhances component performance.

3.Modular T-slot profiles simplify assembly and support automation.

Aerospace

Aerospace engineers trust my aluminum profiles for critical structures like fuselages and wing frameworks. Wrought aluminum alloys provide the strength and flexibility needed for weight-bearing applications. I focus on precision manufacturing to meet strict industry standards. The corrosion resistance of my profiles ensures long service life, even in challenging environments. Companies such as Norsk Hydro have expanded their extrusion capabilities to serve the aerospace and electric vehicle markets.

1.Extruded aluminum offers a superior strength-to-weight ratio.

2.Modular profiles enable efficient, flexible assembly.

3.Aerospace applications demand high reliability and safety.

| Sector / Region | Measurable Data / Performance Indicator |

| Shapes Segment (Product) | Earned USD 39.91 billion in 2023, driven by demand for customized profiles in construction, automotive, aerospace sectors. |

| Building & Construction | Held 36.51% market share in 2023, reflecting demand for lightweight, durable, corrosion-resistant aluminum materials. |

| Shear Assisted Processing and Extrusion (Technology) | Reduces energy use by 50%, increases extrusion speed, and enables recycling of post-consumer aluminum, enhancing sustainability and production efficiency. |

Energy & Electronics

Photovoltaic

I supply aluminum profiles for photovoltaic panel frames and mounting systems. These profiles provide the strength and corrosion resistance needed for outdoor installations. Their lightweight nature simplifies transport and assembly. I design custom solutions to fit various panel sizes and site conditions. The use of aluminum supports the renewable energy sector’s push for sustainability, as these profiles are fully recyclable.

Radiators

Aluminum profiles play a key role in radiators for electronics and industrial equipment. I choose alloys with high thermal conductivity to ensure efficient heat dissipation. The modular design of these profiles allows for easy integration into different systems. My clients in the electronics industry value the durability and low maintenance requirements of aluminum radiators. Series 1 aluminum alloys, known for their electrical conductivity and corrosion resistance, are especially popular in these applications.

Tip: T-slot aluminum profiles offer modularity and flexibility, making them ideal for both energy and electronics projects.

Furniture & Industry

Furniture

I see a growing demand for aluminum profiles in the furniture sector across Africa. Designers and manufacturers choose my profiles for their strength, light weight, and modern appearance. I supply profiles for a wide range of furniture, including office desks, cabinets, wardrobes, shelving units, and modular systems. My clients appreciate the flexibility that aluminum offers. They can create sleek, minimalist designs or bold, industrial looks.

I provide several surface finishes, such as anodizing and powder coating, which help furniture resist scratches and stains. These finishes also allow for a variety of colors and textures. My wood grain transfer technology gives aluminum profiles the appearance of real wood, which appeals to customers who want a natural look without the maintenance issues of timber.

Tip: Aluminum furniture profiles are easy to assemble and disassemble. This feature makes them ideal for modular office spaces and rental properties.

Here are some key advantages my aluminum profiles bring to furniture projects:

1.Durability: Aluminum resists corrosion and wear, ensuring long-lasting furniture.

2.Lightweight: Easy to transport and install, reducing labor costs.

3.Eco-Friendly: Aluminum is fully recyclable, supporting green building goals.

4.Customization: I offer profiles in custom shapes and sizes to match any design.

| Feature | Benefit for Furniture |

| Anodized Finish | Scratch and stain resistance |

| Wood Grain | Natural look, low maintenance |

| Modular Design | Flexible assembly |

I work closely with furniture makers to develop new solutions. My technical team helps with drawings, samples, and assembly guides. I believe that collaboration leads to better products and satisfied customers.

Machinery

Industrial machinery relies on strong, precise, and adaptable components. I supply aluminum profiles for machine frames, conveyor systems, workbenches, safety guards, and automation equipment. My T-slot profiles are especially popular. They allow engineers to build and modify structures quickly, without welding or heavy tools.

I use high-strength alloys to ensure that my profiles handle heavy loads and vibrations. My advanced extrusion process guarantees tight tolerances, which is critical for machinery that requires exact alignment. I offer accessories such as connectors, brackets, and end caps to simplify assembly.

Many African factories have upgraded their production lines using my modular aluminum systems. They report faster installation times and easier maintenance.

Key benefits of my aluminum profiles for machinery include:

1.Strength: Supports heavy equipment and dynamic loads.

2.Precision: Maintains alignment for moving parts.

3.Versatility: Adapts to changing production needs.

4.Safety: Smooth edges and custom guards protect workers.

I provide technical support throughout the project. My engineers assist with layout planning, load calculations, and on-site troubleshooting. I want every client to achieve efficient, safe, and cost-effective operations with my aluminum solutions.

I have built my reputation on delivering Aluminum profiles for doors and Windows that meet the highest standards. My clients trust my quality, value my customization options, and rely on my dedicated service. Visiting my facility gives you confidence in every deal. I invite you to contact me or plan a visit. Let me help you achieve success with your next project. 🏢

FAQ

What is the minimum order quantity for aluminum profiles?

I accept flexible order quantities. For most standard profiles, I start at 500 kilograms per design. For custom profiles, I discuss the minimum based on your project needs.

How do I request a custom profile design?

You can send me your drawings or samples. My engineering team reviews your requirements and creates a technical drawing for your approval. I provide samples before mass production.

What surface treatments do you offer?

I offer anodizing, powder coating, wood grain transfer, and electrophoresis. Each treatment improves durability and appearance. You can choose from a wide range of colors and finishes.

How long does delivery to Africa take?

Delivery time depends on your location and shipping method. Full container loads usually arrive in 30–40 days. Air freight for urgent orders takes 7–10 days.

Do you provide installation support?

Yes, I provide installation guides, videos, and technical consultation. My engineers answer your questions by phone, email, or video call. I want your project to succeed.

What warranty do you offer on your aluminum profiles?

I offer up to 10 years of warranty coverage. My warranty covers manufacturing defects, surface finish issues, and structural failures under normal use. I respond quickly to any claims.

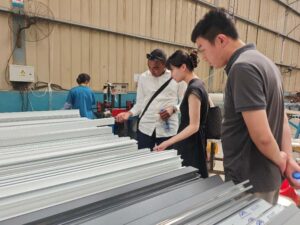

Can I visit your factory before placing an order?

Absolutely! I welcome all clients to visit my facility. You can tour my production lines, see live demos, and discuss your project with my team. I believe in building trust through transparency.