I see how door and window aluminum profiles have become essential in modern construction. Their lightweight structure, strong durability, and resistance to corrosion support projects in harsh environments. I often rely on their energy efficiency and design flexibility to meet both functional and aesthetic needs. Recent industry reports highlight these benefits:

| Benefit | Description |

| Durability | Forms a natural oxide layer, resists rust, and lasts longer with less maintenance. |

| Energy Efficiency | Thermal break technology and finishes improve insulation and lower cooling costs. |

| Design Flexibility | Custom shapes suit unique architectural and structural demands. |

With over 30 years in this field, I have seen JIJU ALUMINIUM’s advanced production and global export reach drive growth. The global market continues to expand, and I always consider how these trends can influence my business decisions.

Key Takeaways

1.Door and window aluminum profiles are lightweight, durable, and corrosion-resistant, making them ideal for modern construction.

2.Energy efficiency is a key benefit of aluminum profiles, helping to lower cooling costs and improve insulation.

3.Emerging markets, especially in Asia-Pacific, are driving demand for aluminum profiles due to urbanization and infrastructure growth.

4.JIJU ALUMINIUM holds important ISO certifications, ensuring high quality and environmental responsibility in its products.

5.Advanced production technologies, like CNC machining, allow for precise and customized aluminum profiles.

6.Sustainable practices, including recycling and energy-efficient processes, are central to JIJU ALUMINIUM’s operations.

7.Strong customer service and support enhance client relationships and ensure satisfaction throughout the project lifecycle.

8.The future of aluminum profiles looks promising, with innovations in materials and manufacturing driving growth in various industries.

Global Trends in Door and Window Aluminum Profiles

As I observe the international market, I see that door and window aluminum profiles have become a cornerstone in modern construction. Their essential role stems from a combination of global trends that continue to shape demand and innovation.

Market Growth Drivers

Construction and Infrastructure Demand

Urbanization and infrastructure development drive the need for advanced building materials. I notice that more cities are expanding, and new buildings require materials that offer both strength and flexibility. Door and window aluminum profiles meet these needs because they are lightweight, durable, and corrosion-resistant. I often recommend them for projects where longevity and minimal maintenance are priorities.

1.The construction sector values:

2.Durable, lightweight, and corrosion-resistant materials

3.Innovations in manufacturing processes

4.Sustainable practices

5.Customization options for unique designs

6.Rapid urbanization, especially in emerging economies

7.Government support for infrastructure and green building

These factors make aluminum profiles a preferred choice for architects and builders worldwide.

Energy Efficiency Requirements

Energy efficiency has become a top priority in building design. I see a growing preference for products that help reduce energy consumption. Door and window aluminum profiles now feature thermal break technology and advanced finishes, which improve insulation and lower energy costs. This shift aligns with stricter building codes and consumer demand for sustainable solutions.

Note: The increasing focus on energy-efficient and visually appealing products continues to influence how manufacturers develop new aluminum profiles.

Regional Market Expansion

Emerging Markets

Emerging markets, especially in the Asia-Pacific region, show rapid growth in demand for door and window aluminum profiles. Urbanization and industrialization in countries like China and India fuel this expansion. I have seen government initiatives in these regions that encourage the use of energy-efficient materials, further boosting the market.

1.Asia-Pacific leads global growth due to:

2.Urbanization and infrastructure investments

3.Supportive government policies

4.Rising disposable incomes in Latin America and the Middle East & Africa

Developed Markets

Developed markets such as North America and Europe maintain steady growth. The construction industries in these regions are mature, but sustainability and energy efficiency have become increasingly important. I notice that the retrofit segment, where older buildings upgrade to modern materials, accounts for a significant share of market revenues.

1.North America and Europe:

2.Experience moderate growth due to mature construction sectors

3.Focus on sustainability and compliance with strict building codes

4.Retrofit projects make up about 35% of total market revenues

JIJU ALUMINIUM has established a strong international presence, exporting to over 20 countries. I believe this global reach allows the company to adapt to diverse market needs and stay ahead of industry trends.

Quality Standards and Certifications

When I work with international clients, I know that strict quality standards and recognized certifications are essential for export success. Door and window aluminum profiles must meet rigorous requirements to ensure safety, performance, and reliability in diverse markets. I always prioritize compliance because it builds trust and opens doors to new opportunities.

International Compliance

ISO Certifications

I have learned that ISO certifications are the foundation of global quality assurance. JIJU ALUMINIUM holds ISO9001, ISO14001, and ISO45001 certifications. These standards demonstrate our commitment to quality, environmental responsibility, and workplace safety.

1.ISO9001 ensures that we maintain standardized and controlled processes, which leads to consistent product quality.

2.ISO14001 shows our dedication to environmentally responsible practices, which matters more to customers every year.

3.ISO45001 confirms our proactive approach to employee safety, enhancing our reputation and trustworthiness worldwide.

Regional Standards

I often encounter different regional standards when exporting. Meeting these standards is crucial for market entry and customer satisfaction. Here is a table that summarizes some of the most recognized international and regional standards for aluminum profiles:

| Standard | Description |

| BS EN 12020 | European standard specifying tolerance on the dimensions and form of extruded precision profiles. |

| EN 755-9 | European standard specifying tolerance on dimensions and forms for aluminum extruded profiles. |

| EN 12020-2 | European quality standard for tolerances and dimensions of extruded precision profiles. |

| ISO 9001 | International standard for quality management systems, ensuring consistent quality in products. |

Quality Control Processes

Advanced Testing

I rely on advanced testing methods to guarantee the quality of every batch. Mechanical tests such as tensile strength and hardness tests help me assess how well the profiles withstand stress and resist deformation. I use tensile testing to measure strength and elasticity, while hardness tests like Brinell, Rockwell, and Vickers evaluate resistance to surface indentation. Fatigue testing allows me to predict how materials behave under repeated stress, and impact tests such as Charpy or Izod help me understand toughness during sudden impacts.

Customer Feedback

Quality control does not end with production. I value customer feedback as a vital part of our continuous improvement process. By listening to clients, I identify areas for enhancement and quickly address any concerns. This approach ensures that our door and window aluminum profiles consistently meet or exceed expectations in every market.

Innovation and Sustainability

Innovation and sustainability shape the future of the aluminum profile industry. I see how these two forces drive market influence and customer preference. Clients now expect advanced technology and eco-friendly practices from every supplier. I have made it a priority to stay ahead by investing in both areas.

Advanced Production Technology

CNC Machining

I use CNC machining to achieve precise dimensions and complex shapes for every project. This technology allows me to deliver consistent quality and meet custom requirements. CNC systems reduce errors and waste, which improves efficiency and supports sustainable manufacturing. I can quickly adapt to new designs and specifications, giving my clients a competitive advantage.

Surface Treatments

Surface treatments play a critical role in enhancing the performance and appearance of aluminum profiles. I apply anodizing, powder coating, and electrophoresis to improve corrosion resistance and extend product life. These treatments also allow for a wide range of colors and finishes, meeting diverse architectural needs. I have seen that advanced surface treatments help maintain the value and durability of door and window aluminum profiles in harsh environments.

Smart technology integration is transforming the industry. I now design profiles that support IoT and smart building systems, which improve energy efficiency and occupant comfort. High-performance profiles with advanced thermal break technology further reduce heat transfer and support sustainable construction.

Sustainable Practices

Environmental Management

Sustainable manufacturing is at the core of my operations. I follow energy-efficient production processes and adhere to Environmental, Social, and Governance (ESG) principles. I monitor resource use and emissions at every stage, ensuring compliance with global standards. I participate in industry-wide sustainability reporting through Environmental Product Declarations (EPD), which increases transparency and trust.

1.I use renewable energy sources, such as hydroelectric power, to reduce my carbon footprint.

2.I integrate sustainability into every operation, from raw material sourcing to product delivery.

3.I support the development of certifications and traceability systems to help clients make informed choices.

Recycling Initiatives

Recycling aluminum is one of the most effective ways to protect the environment. I use recycled materials whenever possible, which reduces energy consumption by up to 95% compared to primary production. Aluminum can be recycled indefinitely without losing quality, making it ideal for a circular economy. Over 75% of all aluminum ever produced remains in use today, which demonstrates its lasting value.

1.I achieve an end-of-life recycling rate of over 90%, minimizing waste and lowering emissions.

2.Increasing recycled content in my supply chain reduces both energy usage and carbon emissions.

3.My recycling practices comply with regulatory frameworks and support global sustainability goals.

The demand for green aluminum continues to rise. I see that companies adopting sustainable practices enhance their brand reputation and gain a competitive edge. My commitment to green manufacturing and resource efficiency positions JIJU ALUMINIUM as a leader in the international market.

Export Experience

Company Background

30+ Years of Expertise

I have witnessed the evolution of JIJU ALUMINIUM since its founding in 1994. Over the past three decades, I have seen the company grow into a leader in the aluminum profile industry. My experience with JIJU ALUMINIUM has shown me the value of long-term commitment and continuous improvement. The company’s journey reflects a dedication to quality, innovation, and customer satisfaction.

Workforce and Facilities

I work with a team that includes more than 1,500 employees. Among them, 32 are senior technical personnel and 69 hold intermediate technical positions. This strong workforce supports our advanced manufacturing capabilities. Our facilities cover 300,000 square meters, which allows us to operate efficiently and scale production to meet global demand. I rely on 21 sets of extrusion equipment ranging from 450T to 7,500T, more than 30 oxidation pools, and multiple vertical and horizontal spray lines. Our CNC machining centers enable us to deliver precise and customized solutions for every project.

I believe that a skilled team and modern facilities form the backbone of reliable production. These resources help me maintain high standards and deliver consistent results.

Here is a summary of our company background:

| Aspect | Details |

| Founded | 1994 |

| Experience | 30 years |

| Area Covered | 300,000 square meters |

| Total Assets | 600 million yuan |

| Number of Employees | More than 1500 |

| Senior Technical Personnel | 32 |

| Intermediate Technical Personnel | 69 |

| Extrusion Equipment | 21 sets (450T-7500T) |

| Oxidation Pools | More than 30 |

| Spray Lines | Vertical and horizontal multiple |

| CNC Machining Centers | Yes |

| Annual Production Capacity | 150,000 tons |

| Certifications | ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 |

| Market Reach | Products sold in China and exported to Europe, Asia, Southeast Asia |

Global Distribution

Export Markets

I have helped JIJU ALUMINIUM expand its reach to more than 20 countries. Our products serve clients in Europe, Asia, and Southeast Asia. I see how our door and window aluminum profiles meet the needs of diverse markets, from large-scale infrastructure projects to residential developments. My experience with international logistics and compliance ensures that every shipment arrives on time and meets local standards.

1.I manage exports to regions with different regulations and customer preferences.

2.I adapt product specifications to match market requirements.

3.I maintain strong relationships with distributors and partners worldwide.

Long-Term Partnerships

I value long-term partnerships with clients and distributors. These relationships build trust and support mutual growth. I focus on reliability, timely delivery, and responsive service. Many clients return to JIJU ALUMINIUM for repeat orders because they trust our expertise and commitment.

My goal is to provide consistent quality and support throughout every stage of the export process. I believe that reliability and service set JIJU ALUMINIUM apart in the global market.

I have seen how our reputation for reliability and service strengthens our position as a preferred supplier. Clients know they can depend on us for high-quality products and professional support.

Applications of Aluminum Profiles

Aluminum profiles have transformed the way I approach design and engineering across many industries. Their versatility and ability to be customized for specific needs make them indispensable in my projects. I rely on their lightweight structure, durability, and corrosion resistance to deliver solutions that meet both functional and aesthetic requirements.

Construction and Architecture

Doors, Windows, Curtain Walls

I use aluminum profiles extensively in construction and architecture. They provide the backbone for doors, windows, and curtain walls, supporting both residential and commercial buildings. The profiles offer strength and stability while allowing for creative design choices. I often select them for projects that demand energy efficiency and minimal maintenance.

Here is a table that highlights common applications and their impact:

| Application | Description | Sustainability Impact | Aluminum Profile Type |

| Structural Framing | Use of aluminum profiles for load-bearing structures, providing strength with lightweight. | Reduces material use, thus lowering carbon footprint. | Rectangular and Square Tubes |

| Window Systems | Aluminum frames and profiles for energy-efficient windows that enhance thermal insulation. | Enhances energy efficiency, reducing heating and cooling costs. | Thermal Break Profiles |

| Facade Cladding | Innovative aluminum panels that provide aesthetic appeal and weather resistance. | Improves building longevity and significantly reduces maintenance. | Aluminum Composite Panels |

| Roofing Systems | Lightweight aluminum roofing profiles that offer durability and reflectivity. | Minimizes heat absorption, thus reducing energy needed for cooling. | Aluminum Roof Panels |

| Solar Panel Mounting | Utilization of aluminum profiles for lightweight and sturdy solar panel frames. | Facilitates renewable energy generation, contributing to sustainability. | Aluminum Extrusions |

I have found that door and window aluminum profiles contribute to building performance in several ways:

| Contribution Aspect | Description |

| Strength and Durability | Aluminum profiles resist environmental pressures and corrosion, ensuring long-term stability. |

| Aesthetic Appeal | They can be customized in various shapes and finishes, enhancing the visual appeal of buildings. |

| Energy Efficiency | Modern profiles include thermal breaks, reducing heat transfer and improving energy conservation. |

| Design Flexibility | Profiles can support large glass spans and accommodate various glass types for specific visual effects. |

| Maintenance | Aluminum’s resistance to wear ensures minimal upkeep is needed for long-lasting performance. |

| Safety and Stability | Engineered to withstand wind loads and seismic activity, ensuring safety in high-rise buildings. |

| Sustainability | Aluminum is 100% recyclable, supporting eco-friendly construction practices. |

Other Industries

Transportation, New Energy, Electronics

I see aluminum profiles playing a vital role in transportation and new energy sectors. In new energy vehicles, I use them for body structures and battery trays to improve efficiency and reduce weight. The solar power industry relies on aluminum profiles for panel frames and mounting systems, which provide durability and support for renewable energy generation.

| Industry | Application Description |

| New Energy Vehicles | Aluminum profiles are used in vehicle body structures, battery trays, and components to enhance efficiency. |

| Solar Power Industry | Aluminum profiles are utilized in solar panel frames and mounting systems, providing durability and support. |

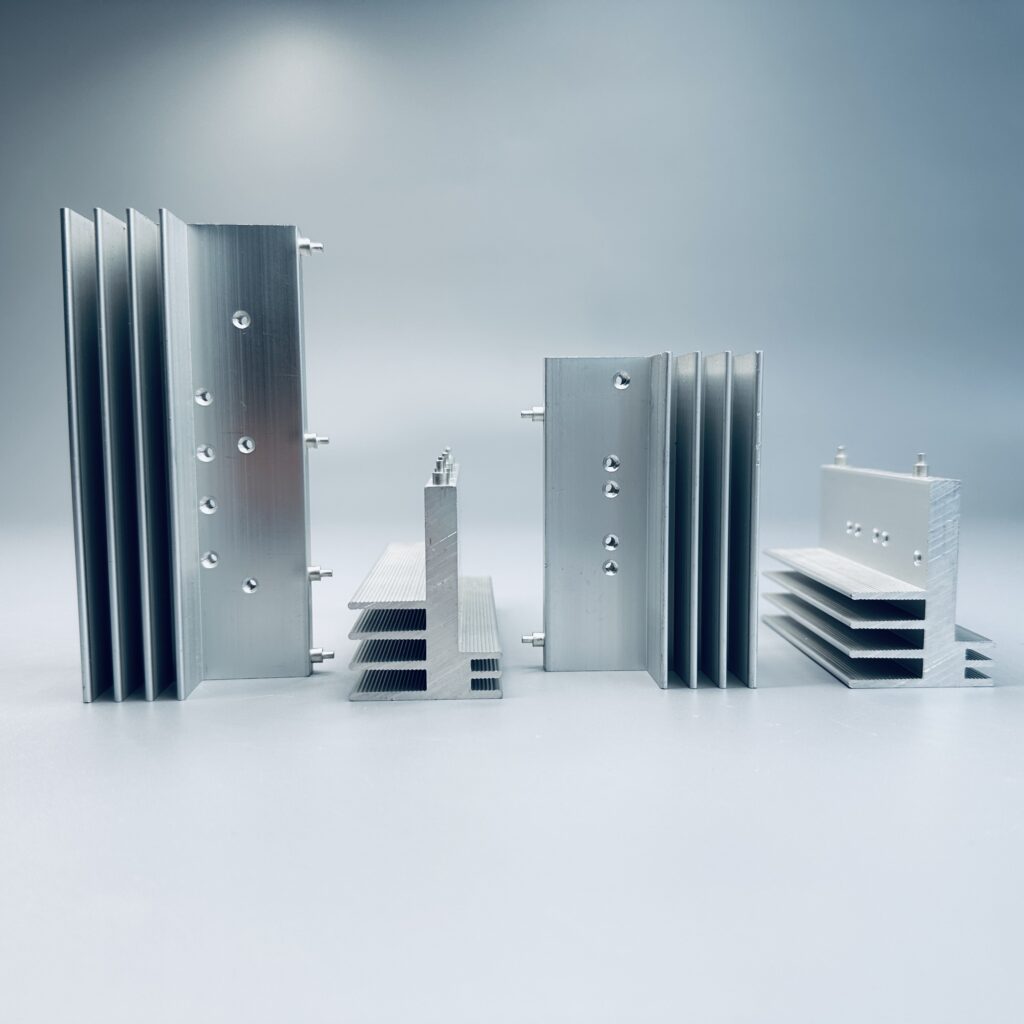

In electronics, I choose aluminum profiles for their ability to dissipate heat and protect sensitive components. Their adaptability allows me to design enclosures and supports that meet precise technical requirements.

Furniture, Machinery, Medical Equipment

Aluminum profiles offer unique advantages in furniture, machinery, and medical equipment. I use them to create modern furniture pieces, such as chair frames and table legs, because they are durable and easy to maintain. In machinery, their strong plasticity and high production efficiency help me deliver reliable solutions for complex systems.

1.Aluminum extruded profiles provide strong plasticity and high production efficiency, making them ideal for medical equipment.

2.Their lightweight and corrosion-resistant nature suits medical beds and stretch frames.

3.I rely on aluminum profiles for precision medical instruments, ensuring easy cleaning and compliance with industry standards.

4.Aluminum furniture resists scratches, stains, and corrosion, making it suitable for various indoor environments.

I have seen how aluminum profiles adapt to diverse applications, supporting innovation and sustainability across industries.

Competitive Advantages

When I consider what sets JIJU ALUMINIUM apart in the global market, I focus on two main pillars: technical expertise and customer service. These strengths allow me to deliver consistent value to clients and maintain a leading position in the industry.

Technical Expertise

Professional Team

I work with a team of highly skilled professionals who bring deep knowledge and hands-on experience to every project. Our engineers and technical staff understand the complexities of aluminum profile production. They stay updated with the latest industry trends and manufacturing technologies. This expertise enables us to tackle challenging requirements and deliver innovative solutions.

1.My team includes specialists in extrusion, surface treatment, and CNC machining.

2.We invest in ongoing training to keep our skills sharp and adapt to new market demands.

3.I encourage collaboration across departments to solve problems quickly and efficiently.

I believe that a strong technical foundation leads to reliable products. My team’s attention to detail ensures that every aluminum profile meets strict quality standards. This commitment to excellence gives clients confidence in our capabilities.

Customer Service

Pre-Sales and After-Sales Support

I place a high priority on customer satisfaction. From the first inquiry to project completion, I provide comprehensive support. My pre-sales service includes technical consultations, product recommendations, and customized design assistance. I listen to client needs and offer solutions that match their specifications and budgets.

After a sale, I continue to support clients with installation guidance, troubleshooting, and maintenance advice. My team responds quickly to questions and resolves issues without delay. This dedication to service has helped me build long-term relationships with customers in both domestic and international markets.

1.I offer clear communication at every stage of the process.

2.My team follows up to ensure products perform as expected.

3.I value feedback and use it to improve our services.

My commitment to high-quality products and excellent service has earned the trust and support of clients worldwide. I see this as the foundation for our continued success and growth.

In my experience, technical strength and customer focus are the keys to standing out in the competitive aluminum profile industry. I strive to exceed expectations and deliver results that help clients achieve their goals.

Future Outlook

Market Opportunities

I see tremendous growth ahead for aluminum profiles in construction and related industries. The construction segment will likely experience the highest compound annual growth rate in the coming years. I attribute this to a surge in infrastructure development and the increasing use of aluminum in interior countertops and cladding. These applications continue to expand market share and drive demand.

1.Construction and infrastructure projects are multiplying, especially in urban areas.

2.Aluminum profiles are gaining popularity in interior design, such as countertops and wall cladding.

3.Green construction and renewable energy systems now rely on aluminum for their lightweight and sustainable properties.

4.New technologies, like carbon-free smelting and AI-driven quality monitoring, are opening new doors for the industry.

5.The shift toward low-carbon economies highlights aluminum’s importance in sustainable infrastructure.

6.In North America, I notice strong growth in aluminum extrusion due to diverse applications and a robust manufacturing base.

I believe these trends will create new opportunities for companies that can innovate and adapt quickly.

Industry Innovations

I stay updated on the latest innovations shaping the aluminum profile market. The next decade promises significant advancements across several fields. I have summarized some of the most impactful innovations in the table below:

| Innovation Type | Description | Application Areas |

| High-End Alloys | 7003-series alloys for new energy vehicle battery trays, achieving 18% elongation. | New Energy Vehicles (NEVs) |

| Aerospace & Electronics | High-purity aluminum (99.99%+) and ultra-fine grain alloys for aircraft. | Aerospace and Electronics |

| Marine Applications | 5083 marine-grade alloy with enhanced anodization for corrosion resistance. | Offshore equipment maintenance |

| Green Transformations | 15 million tons of recycled aluminum by 2027, 30% clean energy use target. | Sustainable aluminum production |

| Intelligent Manufacturing | AI-powered quality control and predictive maintenance systems. | Smart factory operations |

I see these innovations transforming how I approach product development and manufacturing. High-end alloys and advanced processing techniques will help me serve new markets, such as electric vehicles and aerospace. Green transformations and intelligent manufacturing will improve efficiency and sustainability.

JIJU ALUMINIUM’s Vision

I remain committed to leading the industry through innovation and sustainability. My vision for JIJU ALUMINIUM focuses on three core principles:

1.I will invest in research and development to create next-generation aluminum profiles.

2.I will expand my use of recycled materials and clean energy to reduce environmental impact.

3.I will adopt smart manufacturing systems to enhance quality and productivity.

I believe that staying ahead of market trends and embracing new technologies will secure JIJU ALUMINIUM’s position as a trusted partner worldwide. My goal is to deliver solutions that support sustainable growth and meet the evolving needs of clients across the globe.

I have seen door and window aluminum profiles transform global construction. JIJU ALUMINIUM leads this change with a focus on quality, innovation, and sustainability. I believe these values drive international success.

I encourage you to choose JIJU ALUMINIUM as your trusted partner for future projects.

The industry keeps evolving. I stay ahead by embracing new trends and technologies.

FAQ

What makes JIJU ALUMINIUM profiles different from others?

I use advanced production technology and strict quality control. My team focuses on innovation and sustainability. I deliver consistent quality and reliable service to every client.

How do I choose the right aluminum profile for my project?

I recommend considering your project’s requirements, such as strength, insulation, and design. I offer technical consultations to help you select the best profile for your needs.

Can JIJU ALUMINIUM customize profiles for unique designs?

Yes, I provide custom solutions. My CNC machining centers and skilled engineers allow me to create profiles that match your specifications and architectural vision.

What certifications does JIJU ALUMINIUM hold?

I hold ISO9001, ISO14001, and ISO45001 certifications. These prove my commitment to quality, environmental responsibility, and workplace safety.

How does JIJU ALUMINIUM support sustainability?

I use recycled materials and energy-efficient processes. I monitor emissions and resource use. My recycling initiatives help reduce environmental impact.

Which countries does JIJU ALUMINIUM export to?

I export to over 20 countries, including regions in Europe, Asia, and Southeast Asia. My products meet diverse international standards.

What after-sales support do you provide?

I offer installation guidance, troubleshooting, and maintenance advice. My team responds quickly to questions and ensures your satisfaction.

How can I request a quote or more information?

You can contact me through my website or email. I respond promptly with detailed information and personalized solutions.