When I select an aluminum profile supplier for my projects, I focus on reliability, product quality, and service. I often face challenges with strength, hardness, and corrosion resistance. Weldability and decorative performance matter, especially for demanding applications. Machinability influences my decision, as does the choice between standard and customized profiles. I trust JIJU ALUMINIUM, a leading Chinese supplier, because the company consistently meets industry standards and delivers solutions tailored to my needs.

Key Takeaways

1.Choose a reliable aluminum profile supplier to ensure quality and performance in your projects.

2.Clarify your project requirements early to match supplier capabilities with your needs.

3.Look for suppliers who comply with national and international standards for quality assurance.

4.Consider customization options to tailor profiles to your specific project requirements.

5.Evaluate the supplier’s commitment to product quality through rigorous testing and certifications.

6.Assess the supplier’s experience and technical support to enhance project outcomes.

7.Prioritize transparent pricing to avoid unexpected costs and make informed decisions.

8.Ensure timely delivery and strong customer support to keep your projects on track.

Project Requirements

Before I choose an aluminum profile supplier, I always clarify my project’s technical and application needs. This step helps me match supplier capabilities to my requirements and ensures a smooth process from design to installation.

Application Needs

Construction and Industry

In construction and industrial projects, I focus on several technical requirements. The profiles must comply with national and international standards, such as GB/T5237, ASTM B221, and JIS H4001. I check for hardness, especially for 6063-T5 material, which should be at least 8 degrees on the Vickers scale. Standard lengths usually measure 6.02 meters, but I sometimes need custom lengths up to 7.5 meters. Cutting accuracy is critical, with errors not exceeding 0.5mm. I also look for suppliers who follow ISO 9001 quality management systems.

| Requirement Type | Specification Details |

| National Standard | Compliance with standards like GB/T5237, ASTM B221, JIS H4001 is essential. |

| Hardness Standard | Hardness for 6063-T5 material should be ≥8 degrees (Vickers hardness). |

| Length Standard | Standard length is generally 6.02 meters, custom lengths can go up to 7.5 meters. |

| Cutting Standard | Cutting error must be ≤0.5mm for proper assembly. |

| Production Standard | Must conform to ISO 9001 quality management system. |

I rely on rigorous quality control procedures. Advanced testing equipment checks size precision, surface finish, and mechanical properties. Regular tests for tensile strength, hardness, and corrosion resistance give me confidence in the profiles I select.

Transportation and Energy

For transportation and energy projects, I consider the purpose of each profile. Weight and load-bearing requirements influence my choices. I look for profiles with excellent strength-to-weight ratios. Thermal conductivity and insulation properties matter, especially in energy applications. Compatibility with other components ensures smooth assembly and reduces potential issues.

1.I always clarify the purpose of the profile for each application.

2.Manufacturer support and customization options help me tailor profiles to my project.

3.Compatibility with other components is essential for efficient assembly.

4.Thermal conductivity and insulation needs guide my selection.

5.Weight and load-bearing requirements determine the profile type.

Profile Specifications

Dimensions and Tolerances

Precise dimensions and tight tolerances are crucial for successful projects. I check that the supplier can deliver profiles with minimal cutting errors and consistent sizing. High-quality profiles must be free from dents and scratches, which can weaken the structure and reduce durability.

Surface Finishes

Surface treatments play a major role in durability and appearance. I prefer profiles with well-sealed surfaces for enhanced corrosion resistance. Anodizing, painting, or powder coating further improves longevity and performance. These finishes also add decorative value, which is important for visible installations.

| Specification Type | Description |

| Lightweight Strength | Custom aluminum profiles provide unmatched advantages like lightweight strength, ideal for precision engineering. |

| Corrosion Resistance | Aluminum profiles inherently have good corrosion resistance, crucial for durability. |

| Cost-Effectiveness | Optimizing project costs through careful material selection, such as using 6063 aluminum, is essential. |

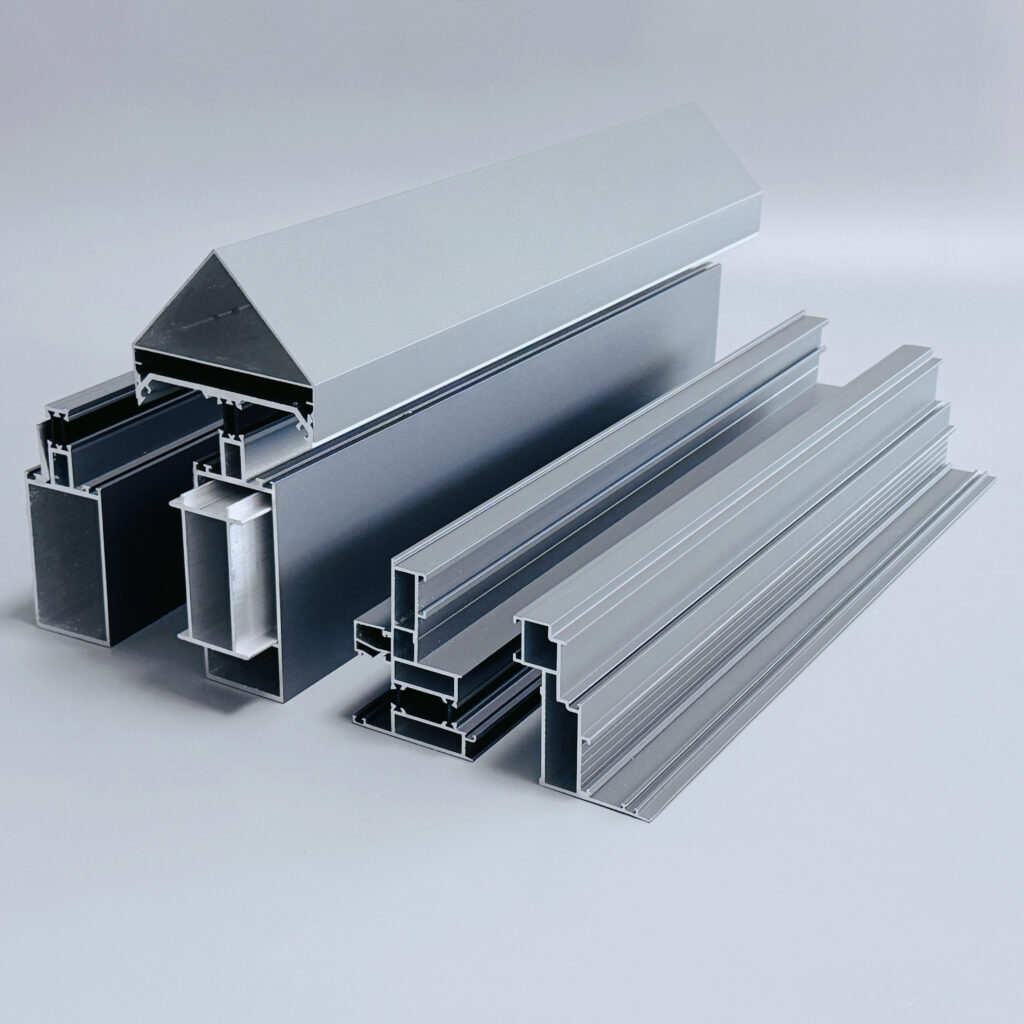

Customization Options

I often need profiles tailored to unique project requirements. Suppliers who offer complex and thin-walled profiles allow me to innovate with my designs. End-to-end customization, from design to production, ensures my specifications are met. Flexible production volumes help me manage prototypes and large-scale orders efficiently. Continuous technical support throughout the project lifecycle optimizes performance and cost.

| Customization Option | Impact on Project Flexibility |

| Complex and thin-walled profiles | Ideal for advanced applications with weight and space constraints, allowing for innovative designs. |

| End-to-end customization | Provides tailored solutions from design to production, ensuring specific requirements are met. |

| Flexible production volumes | Adapts to project needs, whether for prototypes or large-scale production, enhancing responsiveness. |

| Continuous technical support | Ensures ongoing assistance throughout the project lifecycle, optimizing performance and costs. |

Tip: I always discuss customization options with my aluminum profile supplier early in the planning stage. This approach helps me avoid delays and ensures the profiles fit my project perfectly.

Product Quality

When I evaluate an aluminum profile supplier, I always start by examining their commitment to product quality. This step is essential because the reliability and performance of my project depend on the supplier’s ability to meet strict standards and maintain consistency.

Material Standards

I pay close attention to the material standards that the supplier follows. International norms set the benchmark for quality and performance. JIJU ALUMINIUM adheres to several recognized standards, which assures me that their products meet global expectations.

1.EN (European Norms)

2.ISO (International Organization for Standardization)

3.AA (Aluminum Association)

4.DIN (German Institute for Standardization)

5.BS (British Standards)

6.AFNOR (French Standardization)

7.UNE (Spanish Standardization)

The composition of aluminum alloys directly affects their mechanical properties. I always check the alloy elements to ensure optimal strength and durability. For example, in 6061-T6 alloy, magnesium enhances strength, silicon improves castability, and copper increases hardness.

| Element | Role in Aluminum Alloys | Acceptable Range (Example: 6061-T6) |

| Magnesium (Mg) | Enhances strength | 0.8–1.2% |

| Silicon (Si) | Improves castability | 0.4–0.8% |

| Copper (Cu) | Increases hardness | 0.15–0.40% |

High-quality raw materials are essential. They influence the durability, mechanical strength, and appearance of aluminum profiles. I rely on suppliers who use premium alloys because these materials ensure corrosion resistance and long-term reliability, especially in construction and automotive applications.

Quality Control

Rigorous quality control processes set leading suppliers apart. I always ask about the procedures in place to guarantee that every profile meets my specifications.

Testing and Inspection

JIJU ALUMINIUM implements a multi-stage quality control system. Each stage focuses on a different aspect of production, from raw material inspection to final packaging.

| Quality Control Process Stage | Description |

| Raw Material Inspection | Verifying alloy composition and checking for surface defects to ensure quality standards. |

| Extrusion Process Control | Monitoring and adjusting parameters like temperature and pressure for consistent output. |

| Surface Quality Assessment | Conducting visual inspections, surface roughness tests, and coating evaluations for standards. |

| Mechanical Properties Testing | Ensuring profiles meet mechanical strength and durability requirements. |

| Final Packaging Inspection | Checking the final product before packaging to ensure it meets all specifications. |

I value suppliers who invest in advanced testing equipment. Regular inspections for tensile strength, hardness, and corrosion resistance give me confidence in the profiles I receive. Independent tests have confirmed that JIJU ALUMINIUM’s 6063-T6 alloy maintains its strength and durability over years of use, making it a reliable choice for critical applications.

Certifications (ISO9001, etc.)

Certifications provide proof of a supplier’s commitment to quality. I always look for internationally recognized certifications when selecting an aluminum profile supplier.

1.ISO 9001: Focuses on quality management.

2.ISO 14001: Pertains to environmental management.

3.ISO 45001: Relates to occupational health and safety.

4.ISO 6362-4:2022: Sets standards for the shape and size of aluminum profiles.

These certifications demonstrate a supplier’s dedication to quality, environmental responsibility, and worker safety. JIJU ALUMINIUM holds multiple international certifications, including ISO 9001 and ISO 14001. Their products also carry CE and RoHS marks, which indicate compliance with European safety and environmental regulations.

Tip: I always request copies of certifications before placing an order. This step helps me verify the supplier’s credentials and ensures my project meets regulatory requirements.

Consistency

Consistency in production is vital for large-scale projects. I rely on suppliers who maintain strict control over every stage of the manufacturing process. JIJU ALUMINIUM uses advanced techniques to ensure uniformity in every batch.

| Stage | Description |

| Preparing the Die | Custom die machined from hardened tool steel, preheated to 932 °F to ensure even metal flow. |

| Heating the Billet | Aluminum billet heated to 932 °F to ensure malleability and prevent defects during extrusion. |

JIJU ALUMINIUM consistently delivers profiles with superior mechanical properties. Their tensile strength reaches 245 N/mm², well above the industry average. Yield strength measures 195 N/mm², which ensures reliable performance in demanding environments.

I trust JIJU ALUMINIUM because they combine international standards, rigorous quality control, and proven consistency. These qualities make them my preferred aluminum profile supplier for projects that demand excellence.

Aluminum Profile Supplier Experience

When I evaluate an aluminum profile supplier, I always look beyond the product itself. The supplier’s experience shapes every aspect of my project, from initial consultation to final delivery. I have learned that a company’s background, technical team, and investment in technology directly influence the reliability and quality of the profiles I receive.

Company Background

A supplier’s history tells me a lot about their reliability. I prefer to work with companies that have a proven track record and a strong foundation in the industry.

Years in Business

JIJU ALUMINIUM has operated for many years, building expertise and trust in the aluminum profile market. I value this longevity because it signals stability and a deep understanding of customer needs. Suppliers with extensive experience tend to maintain stable relationships and deliver consistent results. My projects benefit from their accumulated knowledge and established processes.

Facility Scale

The scale of a supplier’s facility matters to me. JIJU ALUMINIUM runs a large, modern manufacturing base equipped to handle both small and large orders. This capacity ensures that my projects, whether custom prototypes or bulk production, receive the same attention to detail. I have seen how a well-equipped facility supports high production capacity, scalability, and the ability to meet tight deadlines.

Note: A supplier’s background influences everything from product quality to customer support. I always check for factors like production capacity, innovation, and global presence before making my decision.

| Factor | Description |

| Product Quality | Consistency, surface finish, and dimensional accuracy are critical for specialized applications. |

| Innovation & R&D | Companies investing in R&D lead with lighter, stronger, and more versatile profiles. |

| Production Capacity & Scalability | Ability to handle large orders without compromising quality is vital for OEMs. |

| Customization Capabilities | Flexibility in design and finishing options differentiates vendors for bespoke applications. |

| Pricing & Lead Times | Competitive pricing and reliable delivery schedules influence procurement decisions. |

| Certifications & Compliance | ISO, ASTM, and industry-specific standards ensure product reliability and safety. |

| Global Presence & Supply Chain | A widespread network reduces lead times and mitigates geopolitical risks. |

| Customer Support & Technical Assistance | Strong after-sales support optimizes installation and maintenance processes. |

Technical Team

The expertise of the technical team sets leading suppliers apart. At JIJU ALUMINIUM, I have direct access to engineers and specialists who understand the complexities of aluminum profile design and manufacturing. Their support helps me solve technical challenges quickly. I appreciate their ability to recommend the best alloys, surface treatments, and fabrication methods for my specific applications.

I often consult with their team during the design phase. Their input ensures that my profiles meet both functional and aesthetic requirements. I have found that strong technical support leads to fewer errors, faster problem resolution, and better overall project outcomes.

| Factor | Explanation |

| Industry Experience | Suppliers with significant experience ensure stable and reliable relationships, enhancing satisfaction. |

| Customer Feedback and References | Gathering feedback helps assess supplier performance, directly impacting customer satisfaction. |

| Delivery and Lead Times | Timely delivery is crucial; suppliers must meet project deadlines to maintain customer trust. |

Equipment and Technology

Advanced equipment and technology drive innovation in the aluminum profile industry. I choose suppliers who invest in state-of-the-art machinery and sustainable processes. JIJU ALUMINIUM uses cutting-edge extrusion lines, automated surface treatment systems, and precision testing equipment. These investments result in higher quality, better consistency, and more customization options for my projects.

I have noticed that top suppliers integrate new technologies to improve product performance and sustainability. For example, JIJU ALUMINIUM employs thermal insulation innovations and lightweight, high-strength alloy development. Their use of recycled materials and eco-friendly production methods aligns with my commitment to sustainability. I also benefit from their ability to embed smart features, such as sensors, into profiles for advanced applications.

| Technology/Equipment | Description |

| Thermal Insulation Innovations | Enhanced thermal break technologies integrated into profiles to reduce heat transfer. |

| Lightweight and High-Strength Designs | Development of high-strength aluminum alloys that reduce weight while maintaining structural integrity. |

| Sustainable and Eco-friendly Solutions | Use of recycled materials and eco-friendly production processes to enhance sustainability. |

| Smart Integration and Customization | Embedding sensors and electronic components for smart building functionalities and customization. |

| Corrosion Resistance Improvements | Advanced surface treatments and coatings to enhance corrosion resistance and longevity. |

Tip: I always ask about the supplier’s latest equipment and technology upgrades. This information helps me ensure that my projects benefit from the most advanced solutions available.

My experience tells me that the right aluminum profile supplier combines a strong company background, a skilled technical team, and advanced technology. JIJU ALUMINIUM consistently delivers on all these fronts, making them my preferred partner for demanding projects.

Customization & Solutions

Tailored Profiles

I always look for suppliers who offer tailored aluminum profiles. My projects often require unique shapes, sizes, and finishes. JIJU ALUMINIUM provides a wide range of customization options. Their engineers work with me to design profiles that fit my exact specifications. I can choose from various alloys, wall thicknesses, and surface treatments. This flexibility allows me to optimize both function and appearance. When I need complex or thin-walled profiles, JIJU ALUMINIUM delivers precise results. Their advanced extrusion technology ensures consistent quality, even for intricate designs. I value their ability to produce prototypes quickly, which helps me test and refine my ideas before moving to full-scale production.

Tip: Early collaboration with the technical team leads to better design outcomes and fewer revisions.

One-Stop Service

I prefer working with suppliers who offer a complete, one-stop service. JIJU ALUMINIUM streamlines the entire process, from initial consultation to final delivery. This approach saves me time and reduces the risk of errors. I benefit from several advantages:

1.Efficiency and Time-Saving: I place orders faster and keep my project timelines on track.

2.Cost-Effectiveness: Bulk buying and streamlined purchasing help me secure better pricing.

3.Quality Assurance: Rigorous quality control ensures every profile meets my standards.

4.Simplified Logistics: JIJU ALUMINIUM manages shipping and delivery, reducing complexity.

5.Enhanced Customer Support: I communicate with a single point of contact, which improves response times.

I find that this integrated service model makes my workflow smoother. I avoid the hassle of coordinating with multiple vendors. JIJU ALUMINIUM’s team handles everything, so I can focus on other aspects of my project.

Application Support

I rely on suppliers who understand the demands of my industry. JIJU ALUMINIUM provides valuable application support across several sectors. Their profiles excel in construction, automotive, industrial equipment, and consumer durable products. I use their aluminum profiles in construction because they resist corrosion. This property lowers maintenance costs and reduces the need for replacements. Architects and builders appreciate the long-term durability and reliability these profiles offer.

JIJU ALUMINIUM’s solutions deliver energy efficiency, durability, and aesthetic appeal. I see these benefits in every project, whether I am working on a building facade, a vehicle frame, or high-end furniture.

| Industry | Valued Features |

| Construction | Energy efficiency, durability, aesthetic |

| Automotive | Functional and aesthetic solutions |

| Furniture | High quality standards |

1.Energy efficiency

2.Durability

3.Aesthetic appeal

I trust JIJU ALUMINIUM to provide expert guidance and technical support. Their team helps me select the right profiles for each application, ensuring my projects meet both performance and design goals.

Pricing & Value

Transparent Pricing

I always prioritize transparency when I evaluate aluminum profile suppliers. Clear pricing helps me plan my budget and avoid unexpected costs. JIJU ALUMINIUM provides detailed quotations that break down every aspect of the project. I receive itemized lists that show material costs, tooling fees, and finishing charges. This approach gives me confidence because I know exactly what I am paying for. I appreciate suppliers who explain how each factor influences the final price. When I understand the pricing structure, I can make informed decisions and compare options effectively.

Cost Breakdown

I look closely at the main components of a cost breakdown for aluminum profile products. Several factors contribute to the total price. I consider die and tooling costs, which often range from $400 to $2,000 depending on the complexity and size of the profile. Complex die designs increase both cost and lead time. Symmetrical profiles usually cost less because they simplify the manufacturing process.

The breakdown includes several key elements:

1.Die and tooling costs

2.Complexity of die design

3.Symmetry of the profile

4.Raw material selection

5.Machine time and tolerances

6.Setup and programming

7.Finishing and secondary operations

I use the following table to analyze how each cost factor impacts the total price:

| Cost Factor | Typical Percentage of Total Cost | Impact on Price |

| Raw Material | 15-25% | Varies by alloy and size |

| Machine Time | 30-50% | Based on complexity and tolerances |

| Setup/Programming | 10-30% | Higher impact on small volumes |

| Finishing/Secondary Operations | 5-20% | Depends on requirements |

Each component plays a role in the overall pricing structure. I pay special attention to raw material selection and part complexity because these factors often determine the final cost. JIJU ALUMINIUM’s transparent breakdown helps me optimize my choices and control expenses.

Long-Term Value

I always consider long-term value when I select an aluminum profile supplier. High-quality products and strong engineering support reduce maintenance costs and improve reliability. JIJU ALUMINIUM delivers consistent quality, which lowers the total cost of ownership over time. I compare suppliers using several criteria, including product quality, technical support, and long-term reliability.

The following table highlights how long-term value can differ between suppliers:

| Supplier | Product Quality | Engineering Support | Long-Term Reliability | Total Cost of Ownership |

| JIJU ALUMINIUM | High | Strong | Excellent | Lower over time |

| Other Suppliers | Variable | Limited | Moderate | Higher over time |

I choose JIJU ALUMINIUM because their profiles maintain performance year after year. Their engineering team supports me throughout the project, ensuring I get the best results. I see the benefits in reduced downtime, fewer replacements, and lower overall costs. This long-term value makes JIJU ALUMINIUM my preferred supplier for aluminum profiles.

Delivery & Service

Lead Times

I always pay close attention to lead times when I select an aluminum profile supplier. Fast and reliable delivery keeps my projects on schedule. JIJU ALUMINIUM consistently meets my expectations for prompt service. I notice that lead times for custom aluminum profiles usually range from 20 to 25 days. When I need expedited delivery, JIJU ALUMINIUM offers options that can reduce the lead time to as little as 7 to 10 days. Several factors influence how quickly I receive my order, including the complexity of the profile, production volume, and finishing requirements.

1.Average lead time for custom aluminum profiles is 20-25 days.

2.Expedited options can reduce lead time to 7-10 days under special circumstances.

3.Lead times for aluminum extrusion can vary significantly based on several factors.

I always discuss my project timeline with the supplier at the start. This approach helps me plan ahead and avoid delays.

Logistics

Reliable logistics play a key role in the success of my projects. JIJU ALUMINIUM uses effective packaging and transportation methods to prevent damage during delivery. I value their attention to detail, especially when shipping large or delicate profiles. Security measures like GPS tracking and secure warehousing give me peace of mind. These steps help mitigate risks such as theft or damage and ensure my profiles arrive on time.

1.Effective packaging and transportation are essential to prevent damage during delivery.

2.Security measures like GPS tracking and secure warehousing help mitigate risks such as theft or damage, ensuring timely deliveries.

3.Streamlining customs handling by preparing necessary documentation in advance reduces delays and enhances reliability.

JIJU ALUMINIUM prepares all customs documentation in advance. This practice streamlines the import process and reduces the risk of delays. I appreciate their proactive approach, which keeps my supply chain running smoothly.

Tip: I always confirm logistics details with my supplier before placing an order. This step helps me avoid surprises and ensures my profiles arrive safely.

Customer Support

Strong customer support sets leading suppliers apart. I rely on JIJU ALUMINIUM for responsive service throughout every stage of my project. Their team answers my questions quickly and provides technical assistance when I need it. I compared JIJU ALUMINIUM’s support with other top suppliers in the industry. The table below highlights the range of services offered by leading companies:

| Supplier | Services Offered |

| Kenan Metal | Exceptional customer service, timely delivery, after-sales support |

| Hydro | Packaging, assembly, logistics, after-service and support |

| Tri-State Aluminum | Exceptional customer support, always available for questions |

| Eagle Aluminum | Outstanding customer service, quick quotes, custom sizes, short lead times |

JIJU ALUMINIUM matches these industry leaders with outstanding customer service, fast quotes, and ongoing support. I always feel confident knowing I can reach their team for help at any time. Their commitment to customer satisfaction makes them my preferred supplier for aluminum profiles.

When I select an aluminum profile supplier, I focus on several key criteria:

1.Evaluate product quality

2.Range of profiles and customization options

3.Supplier experience

4.Lead time and delivery reliability

5.Technical support and customer service

6.Price and value

JIJU ALUMINIUM excels in every area. Over three decades of experience, advanced production capabilities, and a strong focus on customization set them apart. For consultations or quotes, I use the following contact methods:

| Method | Details |

| INFO@jijualuminium.com, service@jijualuminium.com | |

| Phone | +8615990909097, +86 13792666821 |

| WhatsApp Link, WhatsApp Link | |

| Video Consultations | Available for complex projects, guiding clients step by step. |

I trust JIJU ALUMINIUM to deliver quality, reliability, and outstanding customer satisfaction.

FAQ

What types of aluminum profiles can I order from JIJU ALUMINIUM?

I can order standard profiles, custom shapes, and thin-walled designs. JIJU ALUMINIUM offers options for construction, transportation, and industrial applications.

How do I request a quote for my project?

I send my drawings or specifications to JIJU ALUMINIUM by email or WhatsApp. Their team responds quickly with a detailed quotation.

What certifications does JIJU ALUMINIUM hold?

JIJU ALUMINIUM holds ISO 9001, ISO 14001, and CE certifications. These credentials assure me of their commitment to quality and safety.

Tip: I always ask for certification copies before placing an order.

How long does delivery usually take?

Delivery for custom profiles usually takes 20 to 25 days. Expedited options are available for urgent projects.

Can I get technical support during the design phase?

I receive technical support from JIJU ALUMINIUM’s engineering team. They help me optimize my designs and select the best alloys.

What surface finishes are available?

JIJU ALUMINIUM offers anodizing, powder coating, and painting. I choose the finish that best suits my project’s durability and aesthetic needs.

| Finish Type | Benefits |

| Anodizing | Corrosion resistance |

| Powder Coating | Color variety |

| Painting | Decorative appeal |

How do I track my order status?

I contact JIJU ALUMINIUM’s customer service or use their logistics tracking system. Updates keep me informed about production and shipping.