I have seen the aluminum profile processing and customization industry grow into a USD 61.48 billion global market. As someone who values innovation and quality, I take pride in JIJU ALUMINIUM’s strengths. With over 30 years of experience, I have watched our company deliver solutions to clients in North America, Europe, and Asia. Our dedication shows in every project. I focus on material quality, precise customization, advanced manufacturing, cost efficiency, and sustainability. These values set us apart in a competitive field.

1.Global market for aluminum profiles projected at USD 61.48 billion by 2025

2.Industry growth rate expected at a CAGR of 8.1% from 2025 to 2030

3.Building & Construction is the largest application segment

4.JIJU ALUMINIUM has over 30 years of experience with a broad international presence

Key Takeaways

1.JIJU ALUMINIUM has over 30 years of experience, ensuring reliable solutions for clients worldwide.

2.The company uses high-quality 6063-T6 aluminum alloy, known for its strength, durability, and corrosion resistance.

3.Advanced surface finishes like anodizing and powder coating enhance the appearance and longevity of aluminum profiles.

4.Customization is key; JIJU ALUMINIUM offers tailored solutions to meet specific project needs, ensuring a perfect fit.

5.The company prioritizes sustainability by minimizing waste and using recycled materials in its production processes.

6.JIJU ALUMINIUM maintains strict quality control with multiple certifications, ensuring high standards in every product.

7.Fast turnaround times of 15 to 30 days for custom orders help clients meet their project deadlines efficiently.

8.A strong international presence allows JIJU ALUMINIUM to serve diverse markets while adapting to local standards.

Material Quality

6063-T6 Alloy Benefits

Fatigue and Deformation Resistance

I always choose 6063-T6 alloy for its outstanding mechanical properties. This alloy stands out in aluminum profile processing and customization because it resists fatigue and deformation even under demanding conditions. I rely on its medium to high strength and excellent extrudability, which make it ideal for complex architectural profiles. The absence of copper in its composition gives it superior corrosion resistance compared to other alloys, such as 6061. This feature ensures that my projects maintain both structural integrity and visual appeal over time.

The Department of Defense has confirmed that 6063-T6 alloy maintains its strength and durability after years of use. I trust this alloy for projects that demand long-term reliability.

Long-Lasting Performance

When I select materials, I look for proven performance. 6063-T6 aluminum delivers consistent results in both strength and longevity. I have seen it perform exceptionally well in real-world applications, from building facades to industrial frameworks. Its mechanical properties support this reputation:

| Mechanical Property | 6063 Aluminum Alloy Value (psi / MPa) |

| Yield Strength | 21000 – 39000 / 145 – 269 |

| Tensile Strength | 27000 – 42000 / 186 – 290 |

| Ultimate Tensile Strength | 470 MPa |

| Fatigue Strength | 150 MPa |

| Modulus of Elasticity | 10000 ksi / 68.9 GPa |

| High Strength-to-Weight Ratio | 270 MPa |

| High Thermal Conductivity | 209 W/m-k |

I have compared 6063-T6 to other alloys in the industry. While 6005 offers higher strength, 6063-T6 provides the best balance of extrudability and corrosion resistance for architectural and industrial uses.

Surface Finishes

Anodizing and Powder Coating

I understand that surface finish plays a critical role in both appearance and protection. At JIJU ALUMINIUM, I use advanced anodizing and powder coating techniques. These processes create a durable, attractive surface that enhances the natural properties of the alloy. Anodizing increases the thickness of the natural oxide layer, while powder coating adds a uniform, colorful finish.

Corrosion Protection

I have seen how these surface treatments extend the lifespan of aluminum profiles. Anodized and powder-coated surfaces resist scratches, fading, and chemical exposure. This protection is essential for outdoor and industrial applications, where harsh environments can quickly degrade untreated materials. My clients appreciate the low maintenance and long-lasting beauty these finishes provide.

Quality Certifications

ISO9001 and International Standards

Quality assurance is at the core of my work. I follow strict quality control at every production stage, using only premium-grade 6063 aluminum billets. Automated systems monitor temperature, pressure, and extrusion speed to ensure consistency. I inspect each batch for surface finish, straightness, and mechanical properties.

JIJU ALUMINIUM holds ISO 9001, CE, RoHS, and SGS certifications. These international standards validate my commitment to quality and safety in every product.

I believe that material quality forms the foundation of successful aluminum profile processing and customization. By combining the best alloys, advanced finishes, and rigorous certifications, I deliver products that exceed expectations.

Customization Capabilities

Aluminum Profile Processing and Customization

Precise Mold Opening

I believe that precision is the foundation of successful aluminum profile processing and customization. When a client brings a unique vision, I start by opening a custom mold that matches their exact specifications. This process allows me to create profiles with complex shapes and tight tolerances. I often receive detailed drawings from clients, which I use to ensure every dimension aligns with their requirements. My team and I use advanced technology to achieve high processing accuracy, which directly improves the quality and fit of each profile.

1.I can open precise molds for any shape or size.

2.Clients submit their own drawings for tailored solutions.

3.Enhanced accuracy leads to better performance in the final product.

4.Technology advancements help me meet diverse application needs.

Tailored Solutions for Projects

Every project has its own challenges. I address these by offering a wide range of customization options. My approach ensures that each client receives a solution designed for their specific application. I work closely with architects, engineers, and manufacturers to understand their goals. This collaboration helps me deliver profiles that fit perfectly, both functionally and aesthetically.

| Customization Attribute | Description |

| Shape | I customize various shapes to fit project needs. |

| Surface Treatment | I offer different finishes to enhance durability and appearance. |

| Length | I cut profiles to the exact length required. |

| Thickness | I provide custom thickness options for structural needs. |

| Color | I supply a range of colors for design flexibility. |

| Tolerance | I specify precision tolerances for an exact fit. |

| Dimension | I adjust dimensions to suit each application. |

My ability to tailor every aspect of the profile ensures that I can support projects in construction, transportation, electronics, and more.

R&D and Innovation

Skilled Professionals and Experts

I rely on a team of skilled professionals who bring years of experience to aluminum profile processing and customization. My engineers and designers stay updated with the latest industry trends and technologies. Their expertise allows me to solve complex design challenges and deliver innovative solutions. I encourage ongoing training and knowledge sharing within my team, which keeps us at the forefront of the industry.

Application-Specific Designs

I know that no two projects are the same. My R&D team works closely with clients to develop application-specific designs. Whether a client needs profiles for curtain walls, automotive parts, or electronic housings, I can adapt my processes to meet those needs. I use advanced software and simulation tools to test designs before production. This approach reduces errors and ensures that the final product performs as expected.

Material Efficiency

Minimizing Waste

Efficiency matters to me, both for cost and sustainability. I optimize every step of aluminum profile processing and customization to minimize material waste. By using precise molds and accurate cutting, I reduce offcuts and scrap. My production planning ensures that I use raw materials effectively, which benefits both my business and the environment.

Maximizing Usable Yield

I focus on maximizing the usable yield from each batch of material. My team analyzes each order to determine the best way to cut and process profiles. This careful planning allows me to deliver more finished products from the same amount of raw aluminum. As a result, I can offer competitive pricing and faster turnaround times.

On average, I complete custom aluminum profile orders within 15 to 30 days, depending on complexity and material availability. This lead time matches or exceeds industry benchmarks, giving my clients a reliable schedule for their projects.

My commitment to customization, innovation, and efficiency sets me apart in the aluminum profile processing and customization industry. I take pride in delivering solutions that meet unique client needs while maintaining high standards of quality and sustainability.

Manufacturing Excellence

Advanced Equipment

Extrusion Lines and CNC Centers

I believe that advanced equipment forms the backbone of any successful aluminum profile manufacturer. At JIJU ALUMINIUM, I operate 21 extrusion lines. These lines allow me to handle a wide range of profile sizes and shapes. I also use state-of-the-art CNC machining centers. These machines help me achieve tight tolerances and complex geometries. With this equipment, I can deliver profiles that meet the most demanding specifications.

My investment in technology ensures that every profile I produce meets high standards for precision and consistency.

Automated and Manual Processes

I combine automation with skilled manual processes. Automated systems handle repetitive tasks like cutting, drilling, and surface finishing. This approach increases efficiency and reduces errors. For custom or intricate work, I rely on my experienced technicians. Their attention to detail ensures that each profile receives the finishing touches it needs. This blend of automation and craftsmanship allows me to maintain both speed and quality.

Large-Scale Production

High Output Capacity

I manage large-scale projects with confidence because of my high output capacity. Each year, I produce up to 150,000 tons of aluminum alloy profiles. This scale allows me to fulfill bulk orders and deliver on time, even for the largest construction or industrial projects.

1.I produce up to 150,000 tons of aluminum alloy profiles annually.

2.My 21 extrusion lines support substantial output and flexibility.

This capacity means I can respond quickly to market demands and client needs.

Skilled Workforce

My team consists of highly trained professionals. I invest in ongoing training to keep my workforce updated on the latest manufacturing techniques. My employees understand the importance of quality at every stage. Their expertise ensures that each order meets client expectations. I value teamwork and communication, which helps me solve challenges efficiently.

Quality Control

Multi-Stage Inspections

Quality control is a priority for me. I implement multi-stage inspections throughout the manufacturing process. I check raw materials before production. During extrusion and finishing, I monitor dimensions, surface quality, and mechanical properties. After production, I conduct final inspections to ensure every profile meets my standards.

Consistent Standards

I maintain consistent standards across all batches. My quality management system follows international guidelines. I document every step, from material selection to final packaging. This approach guarantees that clients receive reliable, high-quality products every time.

My commitment to manufacturing excellence ensures that every aluminum profile I deliver stands up to the highest expectations for performance and reliability.

Cost Efficiency

Material Optimization

Efficient Raw Material Use

I always prioritize efficient use of raw materials in my production process. I select high-quality aluminum billets and plan each extrusion to maximize output. My team uses advanced software to map out the best cutting patterns. This approach helps me reduce leftover material and ensures that every kilogram of aluminum serves a purpose. By focusing on efficiency, I can lower production costs and pass those savings on to my clients.

Scrap Reduction

Scrap reduction stands as a key part of my cost strategy. I monitor every stage of production to identify areas where waste might occur. My technicians adjust machine settings and review cutting plans regularly. When I see excess scrap, I investigate the cause and implement corrective actions. This attention to detail allows me to keep waste levels low and maintain a cleaner, more sustainable operation.

Streamlined Production

One-Stop Service

I offer a one-stop service that covers everything from design consultation to final delivery. Clients can rely on me for mold design, extrusion, surface treatment, and packaging. This integrated approach eliminates the need for multiple suppliers. I coordinate every step, which reduces delays and avoids miscommunication. My clients appreciate the convenience and efficiency of working with a single, experienced partner.

Fast Turnaround

Speed matters in today’s market. I have optimized my workflow to deliver fast turnaround times. My production lines operate with minimal downtime. I schedule jobs efficiently and keep a close eye on inventory levels. Most custom orders leave my facility within 15 to 30 days. This reliability helps my clients meet their own project deadlines and reduces costly waiting periods.

My streamlined process means clients receive their products quickly, without sacrificing quality or precision.

Competitive Pricing

Economies of Scale

My large-scale production capacity allows me to offer highly competitive prices. I purchase raw materials in bulk, which lowers my input costs. I also benefit from efficient logistics and automated systems. These factors combine to create significant savings for my clients.

To illustrate how my pricing compares to others in the industry, consider the following table:

| Company Name | Est. Price ($/kg) | Min. MOQ | Key Attributes |

| Shandong Jiju Aluminum Industry Co., Ltd. | $1.50 – $2.00 | 1 kg | Low MOQ, significant volume discount |

| CITIC METAL MANUFACTURING CO., LTD | $1.70 – $3.20 | 100 kg | Tiered volume discounts |

| Foshan Newtop Aluminium Factory Co., Ltd. | $2.20 – $2.80 | 5000 kg | High MOQ, large volume discount |

| Shandong Tiancheng Xingye Aluminum Products Co., Ltd. | $2.14 – $2.54 | 500 kg | Volume discounts, construction focus |

| Anhui Shengxin Aluminium Corporation Limited | $1.60 – $2.70 | 3 tons | Very competitive bulk pricing, anodized option |

I set my minimum order quantity as low as 1 kg, which gives small and large clients flexibility. My price range remains among the lowest in the market, especially for bulk orders. This pricing structure, combined with my efficient processes, makes JIJU ALUMINIUM a smart choice for cost-conscious buyers.

Sustainability

Eco-Friendly Production

Waste Reduction Methods

I always look for ways to make my production process more sustainable. At JIJU ALUMINIUM, I focus on reducing waste at every stage. I use recycled aluminum whenever possible. This choice helps me conserve natural resources and cut down on energy use. I also invest in advanced technologies that optimize energy consumption. These systems help me lower my carbon footprint and support a circular economy. I believe that every small change can make a big difference for the environment.

Here is a summary of the main eco-friendly initiatives I have implemented:

| Initiative/Method | Description |

| Use of Recycled Materials | I prioritize recycled aluminum to reduce environmental impact, conserve resources, and minimize energy consumption. |

| Energy-Efficient Practices | I employ advanced technologies to optimize energy use and reduce my carbon footprint, supporting the circular economy. |

| Integration of Renewable Energy Sources | I incorporate solar and wind power to reduce reliance on fossil fuels and align with global sustainability goals. |

I also monitor my production lines closely. I track scrap rates and adjust my processes to minimize leftover material. My team and I review each step to find new ways to cut waste. I see this as a responsibility to both my clients and the planet.

Environmentally Friendly Products

I design my products to have a positive impact on the environment. Aluminum itself is highly recyclable. I make sure my profiles can be reused or recycled at the end of their life cycle. My surface treatments, such as anodizing and powder coating, use eco-friendly materials and processes. I avoid harmful chemicals and follow strict environmental guidelines. My clients often ask for green solutions, and I am proud to deliver products that meet those expectations.

�� I believe that sustainable manufacturing is not just a trend. It is a commitment to future generations.

Certifications

ISO14001 and ISO45001

I understand that certifications matter to my clients. They show that I meet international standards for environmental management and workplace safety. JIJU ALUMINIUM has achieved the following certifications:

ISO14001:2015

ISO45001:2018

These certifications prove that I manage my environmental responsibilities effectively. I also ensure a safe and healthy workplace for my employees.

Safe Work Environment

I take the safety of my team seriously. I provide regular training and maintain strict safety protocols. My facilities use modern ventilation and dust control systems. I encourage open communication about safety concerns. My goal is to create a workplace where everyone feels protected and valued.

I see sustainability as a journey. Every year, I set new goals to improve my environmental performance and workplace safety. My commitment to eco-friendly production and certified standards sets JIJU ALUMINIUM apart in the industry.

Application Versatility

Construction and Architecture

Doors, Windows, Curtain Walls

I have seen the construction industry demand materials that balance strength, weight, and design flexibility. My aluminum profiles meet these needs for doors, windows, and curtain walls. I select lightweight alloys that simplify installation and reduce structural load. Architects appreciate the slim sightlines and modern aesthetics my profiles provide. I offer a range of finishes, so clients can match any building style. My profiles resist corrosion, which ensures long-term durability even in harsh climates. I work closely with project teams to customize dimensions and surface treatments. This approach guarantees a perfect fit for every architectural vision.

Note: Aluminum profiles are lighter than traditional steel profiles, making them ideal for construction projects that require both strength and ease of handling.

Transportation and Energy

Automotive, Aerospace, Photovoltaics

I recognize that transportation and energy sectors require advanced solutions. My aluminum profiles play a key role in automotive, aerospace, and photovoltaic applications. I help manufacturers reduce vehicle weight, which improves fuel efficiency and lowers emissions. My profiles provide sustainable alternatives to heavier materials. I supply components for cars, airplanes, and trains, where high strength and low weight are critical.

1.I reduce the weight of vehicles, which enhances fuel efficiency.

2.I provide sustainable alternatives in transportation solutions.

3.My profiles apply to various sectors, including cars, airplanes, and trains.

| Advantage | Description |

| Lightweight | My aluminum profiles weigh less than steel, which benefits construction and transportation. |

| High Strength | My profiles maintain high strength, which suits demanding aerospace and automotive applications. |

In the energy sector, I design profiles for photovoltaic frames and mounting systems. My corrosion-resistant finishes ensure reliable performance outdoors. I support renewable energy projects by delivering products that last.

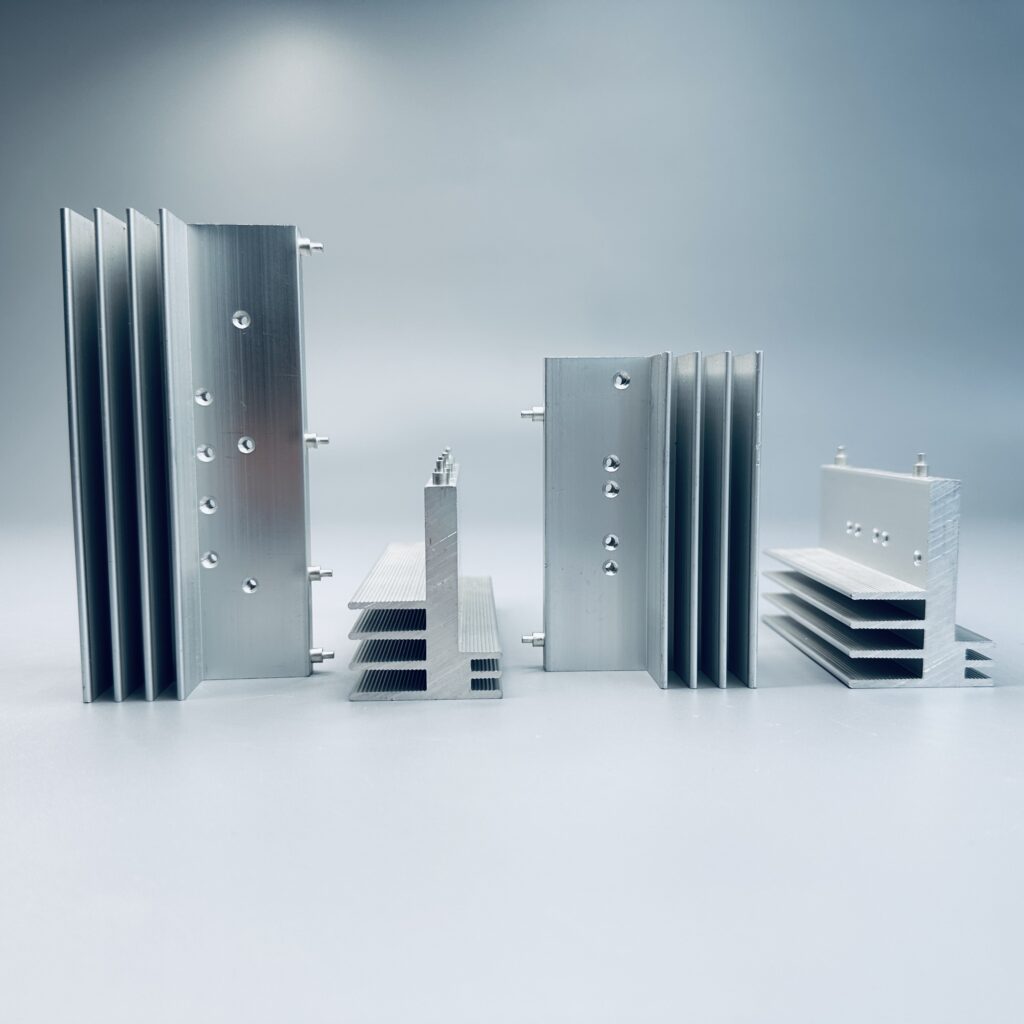

Electronics and Industry

Heat Sinks, Machinery, Medical Devices

I understand that electronics and industrial equipment require precision and reliability. My aluminum profiles serve as heat sinks, which help manage thermal loads in electronic devices. I manufacture components for machinery that demand tight tolerances and consistent quality. My profiles also appear in medical devices, where hygiene and safety matter most.

1.Automotive components

2.Aerospace construction

3.Electrical applications

I tailor each solution to the specific requirements of the industry. My team collaborates with engineers to optimize designs for performance and manufacturability. I believe that versatility sets JIJU ALUMINIUM apart. My profiles adapt to a wide range of applications, from skyscrapers to solar farms to advanced electronics.

Certifications and Support

Global Standards

Quality and Environmental Certifications

I know that certifications matter when clients choose a reliable aluminum profile supplier. At JIJU ALUMINIUM, I make sure every product meets strict international standards. These certifications prove my commitment to quality, safety, and sustainability. I keep my processes transparent and my products consistent. Here is a summary of the key certifications I maintain:

| Certification | Description |

| ISO 9001 | Ensures products and services meet high standards of quality and reliability, focusing on efficiency and customer satisfaction. |

| IATF 16949 | Meets high quality management standards for the automotive industry, ensuring optimized processes for delivering quality components. |

| ISO 14001 | Highlights commitment to sustainability and environmental management, minimizing environmental impact. |

| SGS | Independent Product Testing |

| CE | European Conformity |

| RoHS | Restriction of Hazardous Substances |

These certifications help me access global markets and assure clients that my products meet both quality and environmental requirements. I update my certifications regularly to stay ahead in the industry.

Technical Support

Pre-Sales and After-Sales Service

I believe that excellent technical support builds trust and long-term relationships. I guide clients through every stage of their project, from the first inquiry to final delivery. My team and I provide:

1.Assistance in product selection to match each client’s needs.

2.Customization options for unique project requirements.

3.Comprehensive customer service before and after sales.

4.High-quality products tailored to customer specifications.

5.Reliable support that enhances the overall purchasing experience.

I listen to my clients and respond quickly to their questions. My support does not end after delivery. I remain available to solve any issues and offer guidance for future projects.

Tip: I recommend reaching out early in your project planning. My technical team can help you avoid costly mistakes and ensure the best results.

International Reach

Export Markets and Global Presence

I have built a strong presence in international markets. My aluminum profiles reach clients in North America, Europe, Asia, and beyond. I understand the requirements of different regions and adapt my products to meet local standards. My export experience allows me to handle logistics efficiently and deliver on time.

I work with partners and distributors worldwide. This network helps me provide fast service and local support. I take pride in seeing JIJU ALUMINIUM products used in projects around the globe. My global reach proves my reliability and commitment to serving clients wherever they are.

I set JIJU ALUMINIUM apart by combining advanced technology, strict quality control, and a focus on customer needs. My recent upgrades include automation, AI integration, and nano-coating, which improve efficiency and product durability. I also lead in sustainability and lightweighting trends.

| Innovation | Customer Benefit |

| Automation & AI | Consistent quality, fewer errors |

| Nano-coating | Longer-lasting, corrosion-resistant profiles |

| Sustainable Practices | Lower costs, eco-friendly products |

I invite you to experience the difference with JIJU ALUMINIUM for your next project.

FAQ

What types of aluminum profiles do I offer?

I provide a wide range of profiles, including standard shapes and fully customized designs. My selection covers architectural, industrial, and specialty applications. I can tailor each profile to meet your exact project requirements.

How do I ensure product quality?

I follow strict quality control at every stage. My team inspects raw materials, monitors production, and checks finished products. I hold ISO 9001 and other international certifications to guarantee consistent quality.

Can I handle small orders or prototypes?

Yes, I accept small orders and prototype requests. My minimum order quantity starts at just 1 kg. I support both large-scale projects and individual custom solutions.

How long does it take to deliver custom profiles?

Most custom orders ship within 15 to 30 days. I optimize my workflow to ensure fast turnaround. I keep clients updated throughout the process.

What surface finishes can I provide?

I offer anodizing, powder coating, and other advanced finishes. These treatments improve durability, appearance, and corrosion resistance. I can match a wide range of colors and textures.

Do I support international shipping?

Yes, I export aluminum profiles worldwide. I understand local standards and manage logistics efficiently. My global network ensures reliable delivery to your location.

How do I help clients choose the right profile?

I provide technical support from the first inquiry. My team reviews your project needs and recommends the best options. I guide you through material selection, design, and finishing choices.